The quest to engineer materials with specific, tailored properties is a cornerstone of modern materials science. This pursuit involves a complex interplay of fundamental scientific principles and advanced technological capabilities. Understanding the intricate relationship between atomic structure and macroscopic behavior is crucial for designing materials with optimized characteristics. This understanding fuels the development of innovative materials for various applications, from high-performance electronics to sustainable energy solutions.

From the nanoscale to the macroscale, precise control over material structure is paramount in achieving desired properties. This control allows researchers to manipulate the arrangement of atoms and molecules, leading to materials with unique functionalities. This multifaceted approach necessitates a deep understanding of the underlying chemical, physical, and mechanical principles that govern material behavior.

Harnessing Advanced Characterization Techniques

Advanced characterization techniques play a vital role in the design process, enabling researchers to probe the intricate structure and properties of materials at various length scales. Electron microscopy, X-ray diffraction, and spectroscopy are crucial tools that provide detailed insights into the atomic arrangement, crystallographic structure, and electronic properties of materials.

These techniques are indispensable in understanding the correlation between material structure and properties, allowing for informed design decisions and optimization of materials performance. By meticulously analyzing the data generated from these techniques, scientists can identify potential design flaws and refine their approaches, leading to more effective materials.

Leveraging Computational Modeling

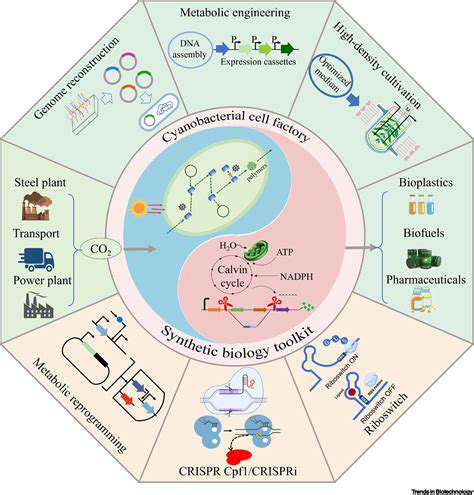

Computational modeling offers a powerful tool for designing and simulating materials behavior before extensive experimental work. Sophisticated software tools allow researchers to predict the properties of materials based on their atomic structure and interactions. This capability enables the exploration of a vast design space, potentially identifying promising candidates for specific applications before any physical synthesis.

Exploring Novel Material Synthesis Strategies

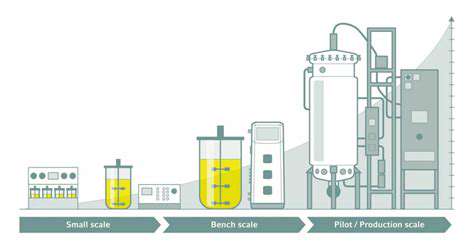

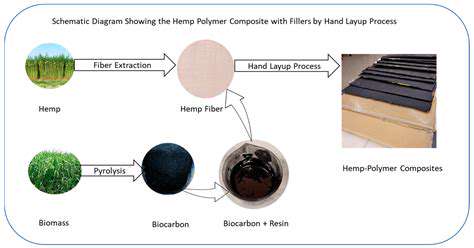

Developing novel material synthesis strategies is critical for realizing the full potential of materials design. These strategies encompass various techniques, including chemical vapor deposition, sol-gel processing, and 3D printing. The choice of synthesis method significantly impacts the final microstructure and properties of the material. Optimizing these techniques is essential for producing materials with precisely controlled composition and morphology.

By meticulously controlling the synthesis parameters, researchers can tailor the material's properties to meet specific needs. This sophisticated control over synthesis ensures that the resulting materials exhibit the desired characteristics for their intended application.

Addressing Challenges and Future Directions

Despite significant advancements, challenges remain in designing materials with desired properties. One notable hurdle is the intricate relationship between structure and properties, which is often not fully understood. Further research is needed to unravel these complexities and develop more predictive models. This knowledge gap necessitates the development of more sophisticated computational tools and experimental techniques to gain deeper insight into the mechanisms governing material behavior.

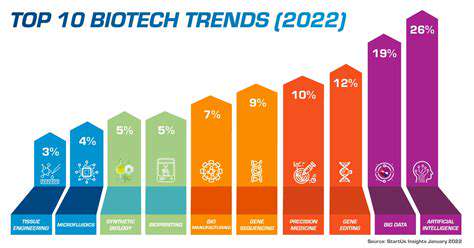

Future directions in materials design include integrating artificial intelligence and machine learning algorithms to accelerate the design process. These approaches have the potential to significantly reduce the time and resources needed for material development, paving the way for more rapid advancements and innovations.

Understanding the fundamental mechanisms of adhesion is crucial for developing effective and durable materials. Adhesion is the attraction between different surfaces, a complex interplay of forces that hold materials together. These forces, which can be van der Waals forces, electrostatic interactions, or chemical bonds, determine the strength and longevity of the bond. The specific types and strengths of these forces dictate the overall performance of materials, particularly in applications where resistance to detachment is paramount.