Exploring the Convergence of Synthetic Biology and Functional Materials

Synthetic biology, a rapidly evolving field, is poised to revolutionize the design and creation of functional materials. This interdisciplinary approach combines biological principles with engineering tools to engineer novel materials with tailored properties. This convergence allows for the creation of materials with unprecedented functionalities, surpassing the limitations of traditional polymer-based materials. By leveraging the inherent capabilities of biological systems, we can develop materials with enhanced performance characteristics, such as improved strength, biocompatibility, and responsiveness to external stimuli.

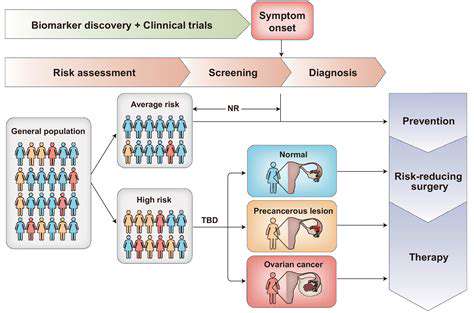

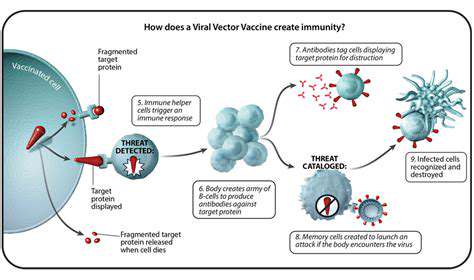

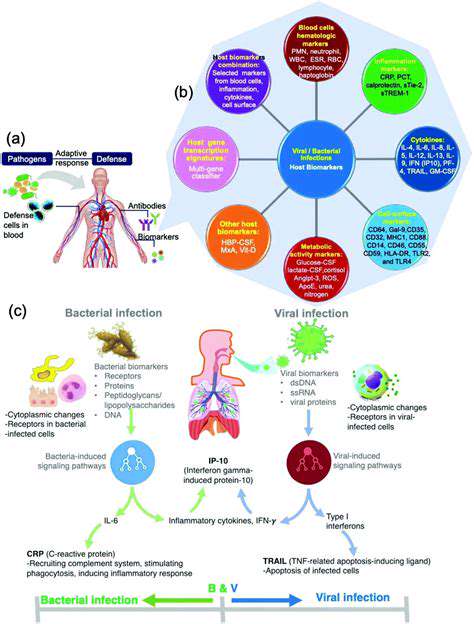

One key aspect of this convergence is the ability to incorporate biological components directly into the material structure. This opens up avenues for creating materials with self-healing properties, mimicking the remarkable resilience of biological tissues. Furthermore, the incorporation of enzymes and other biocatalysts within the material matrix allows for the development of smart materials that respond dynamically to environmental changes, opening up exciting possibilities for applications in sensors, actuators, and drug delivery systems.

Tailoring Material Properties Through Biological Mechanisms

The inherent variability and adaptability of biological systems offer unparalleled opportunities for tailoring material properties. By harnessing the power of genetic engineering, we can modify the properties of biological components to precisely control the characteristics of the resulting functional materials. This includes manipulating the size, shape, and functionality of proteins, enzymes, and other biomolecules to achieve desired material properties. We can anticipate materials with enhanced conductivity, improved optical characteristics, and tailored interactions with specific molecules.

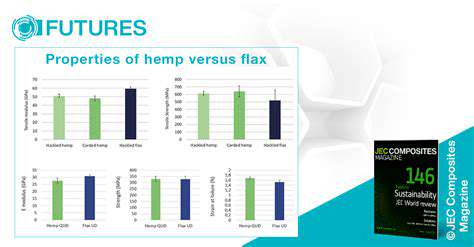

Furthermore, the use of biological mechanisms for self-assembly and hierarchical organization presents a powerful tool for creating complex and intricate material structures. Mimicking the intricate architectures found in nature, we can engineer materials with enhanced mechanical strength, improved durability, and unique functionalities. This approach can lead to the development of novel composites and hybrid materials with superior properties compared to traditional materials.

Applications and Challenges in the Field

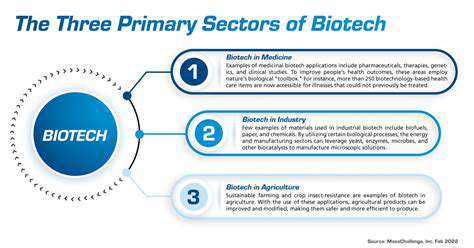

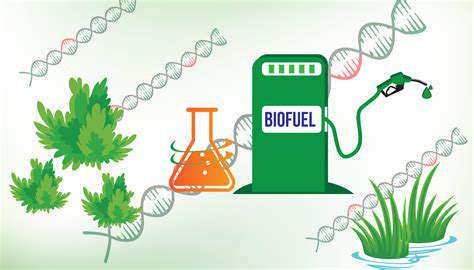

The potential applications of synthetic biology in functional materials are vast and span numerous sectors. In the biomedical field, biocompatible materials with enhanced drug delivery capabilities are emerging. In the energy sector, self-healing polymer composites with improved performance in demanding environments are being developed. Moreover, in the electronics industry, novel materials with tailored optical and electrical properties are gaining traction.

Despite the promising potential, several challenges remain in the field. The precise control over the incorporation and functionality of biological components in materials is still a significant hurdle. Furthermore, the scalability of these processes to industrial production levels is crucial for widespread adoption. Addressing these challenges will pave the way for the widespread implementation of synthetic biology-driven functional materials across diverse applications.

The Future of Materials Science: A Bio-Inspired Approach

Exploring Novel Materials for Sustainable Solutions

The field of materials science is undergoing a transformative period, driven by the urgent need for sustainable solutions to global challenges. Researchers are actively seeking new and innovative materials with enhanced properties, reduced environmental impact, and improved performance characteristics. This includes exploring materials derived from renewable resources, optimizing existing materials for efficiency, and developing entirely new classes of materials with tailored functionalities. The focus on sustainability is paramount, aiming to minimize waste generation and resource depletion during the lifecycle of the materials.

One critical aspect of this exploration is the development of materials capable of withstanding extreme conditions. These materials play a crucial role in various sectors, such as aerospace, energy production, and construction. Scientists are pushing the boundaries of material science to create materials that are both durable and lightweight, offering significant advantages in terms of performance and efficiency. This advancement is critical for meeting the demanding requirements of future technologies.

Advancements in Manufacturing and Processing Techniques

The future of materials science hinges not only on the discovery of new materials but also on the development of innovative manufacturing and processing techniques. These techniques are vital for translating promising material discoveries into practical applications. Modern approaches are focused on optimizing existing processes, reducing energy consumption, and minimizing waste generation in manufacturing. This holistic approach to manufacturing is essential for achieving the desired environmental and economic benefits.

Advanced techniques like 3D printing and additive manufacturing are revolutionizing the way materials are fabricated. These methods enable the creation of complex geometries and intricate structures, unlocking new possibilities for material design and application. The ability to tailor material properties at the nanoscale through these advanced manufacturing processes will undoubtedly lead to significant advancements in various sectors.

The Interdisciplinary Nature of Material Science

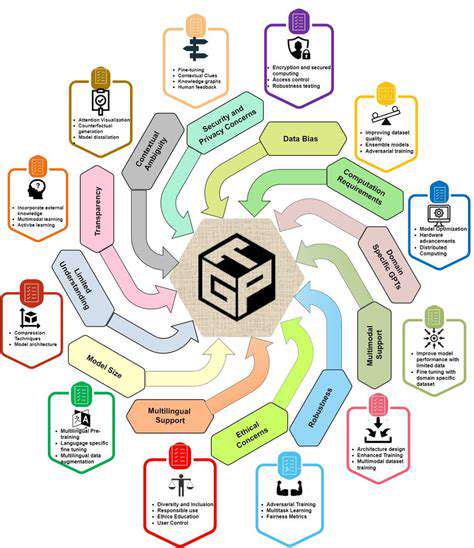

Materials science is no longer a discipline confined to a single area of expertise. Its future rests on the collaborative efforts of scientists from diverse backgrounds, including chemistry, physics, engineering, and computer science. This interdisciplinary approach fosters a richer understanding of materials at multiple scales, from the atomic to the macroscopic level. This synergistic environment allows for the development of more sophisticated and effective solutions to complex challenges.

The integration of computational modeling and simulation techniques is another key element in this interdisciplinary approach. These tools allow scientists to predict the behavior of materials under various conditions, accelerating the design and development process. This accelerated pace of innovation is vital for addressing the critical needs of the 21st century.