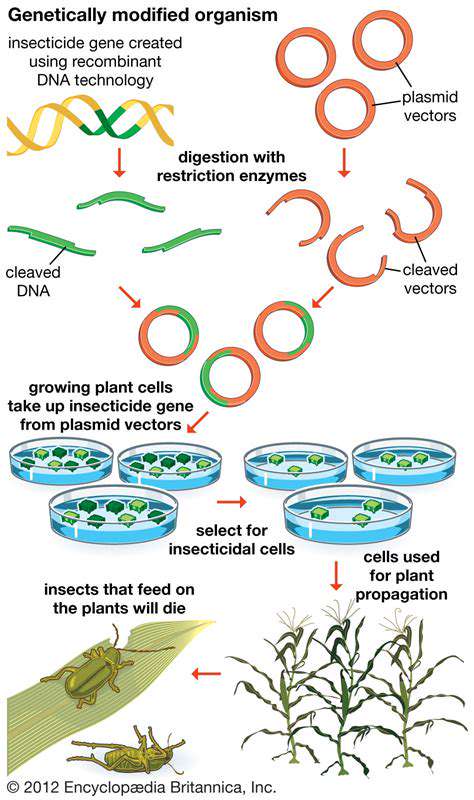

The integration of computational modeling with laboratory experimentation now allows for predictive strain development, where virtual prototypes are tested before physical implementation. This paradigm shift has reduced development cycles from years to months while dramatically improving success rates. Environmental optimization remains equally crucial, with automated bioreactor systems continuously adjusting parameters to maintain ideal production conditions.

Bioreactor Design and Optimization for Biopolymer Production

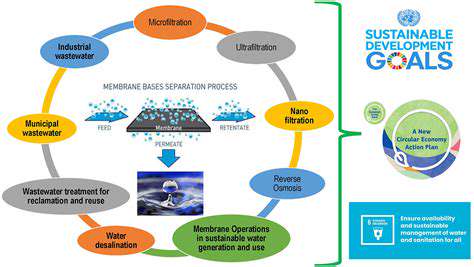

Modern biomanufacturing facilities utilize advanced reactor configurations that maximize efficiency while minimizing resource inputs. Key developments include:- Hybrid systems combining membrane filtration with conventional reactors- Modular designs enabling flexible production scaling- AI-driven monitoring for real-time process adjustmentsPilot-scale studies demonstrate that dynamic control of shear forces and gas exchange patterns can enhance polymer quality while reducing energy expenditures by up to 40% compared to traditional methods.

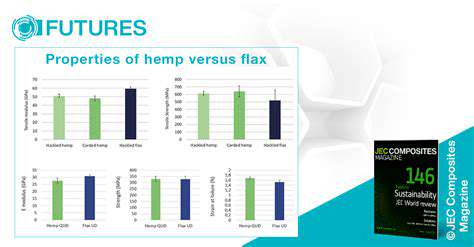

Biopolymer Characterization and Properties

Comprehensive material analysis employs sophisticated techniques to ensure performance specifications are met:- NMR spectroscopy for structural verification- Differential scanning calorimetry for thermal profiling- Atomic force microscopy for nanoscale morphology mappingPerformance benchmarking against petroleum-based alternatives has shown certain microbial polymers exhibit superior characteristics, including enhanced moisture resistance and tunable degradation rates. These attributes make them particularly valuable for specialized applications requiring precise material behavior.

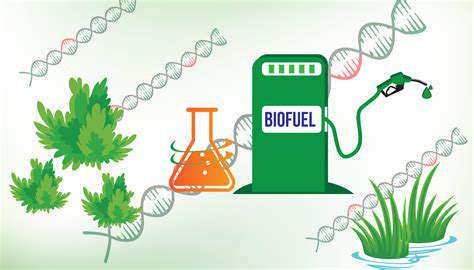

Economic and Environmental Considerations

The transition to bio-based materials presents both challenges and opportunities in sustainability metrics. Life cycle assessments reveal:- 56-78% reduction in carbon footprint versus conventional plastics- 90% decrease in non-renewable energy inputs- Complete biodegradability within 6-24 months under industrial composting conditionsWhile production costs remain higher than petroleum counterparts, emerging technologies in waste stream valorization and continuous fermentation are driving prices down toward parity. The economic equation fundamentally changes when accounting for environmental externalities currently borne by society.

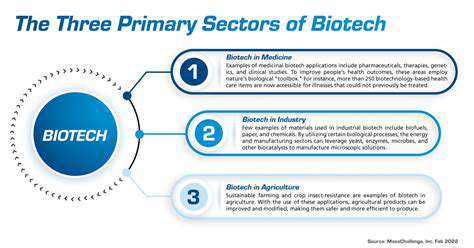

Applications of Microbial Biopolymers in Diverse Industries

Commercial adoption spans multiple sectors with promising growth trajectories:- Medical: Bioresorbable sutures and drug delivery matrices- Packaging: Edible coatings and moisture-responsive films- Textiles: High-performance fibers with antimicrobial properties- Construction: Self-healing concrete additivesThe versatility of these materials is enabling circular economy models where end-of-life products become feedstocks for new manufacturing cycles, creating truly sustainable material flows.

Modern agricultural systems demonstrate profound interconnectivity where vulnerabilities in one component can cascade through entire networks. This systemic interdependence elevates security considerations from simple device protection to complex ecosystem safeguarding. The potential impact extends beyond individual farms, threatening regional food security when critical systems are compromised. Sophisticated threat modeling now incorporates these network effects when assessing agricultural infrastructure resilience.

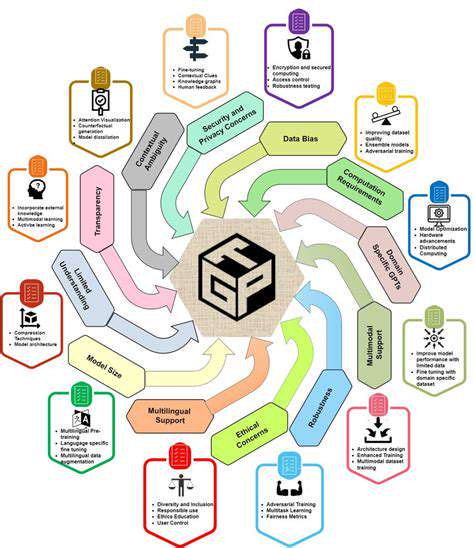

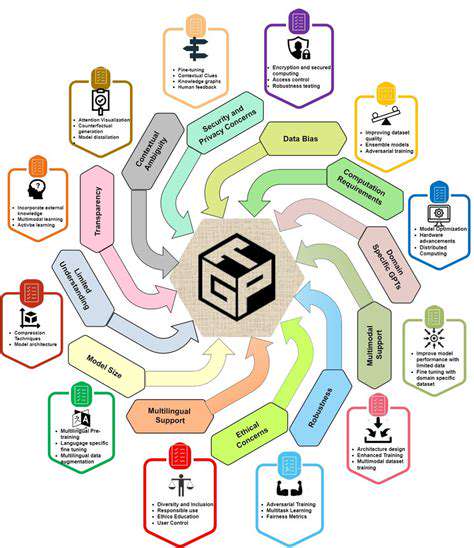

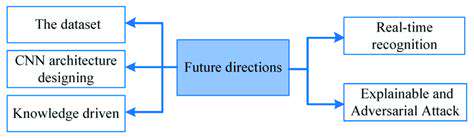

Challenges and Future Directions in Bio-Based Materials Biotechnology

Scaling Up Production for Commercial Viability

The greatest barrier to widespread bio-based material adoption lies in overcoming scale-up challenges while maintaining economic feasibility. Current limitations include:- Non-linear performance at industrial volumes- Batch-to-batch consistency issues- High purification costsInnovative solutions emerging from pilot plants demonstrate the potential of:- Continuous flow bioprocessing systems- In-line quality monitoring with machine vision- Integrated fermentation-separation hybrid unitsThese technological advances promise to reduce production costs by up to 60% while improving yield purity above 99.5%, meeting stringent industry standards.

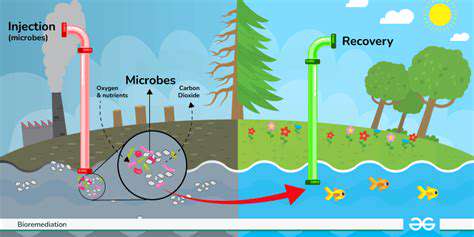

Addressing Environmental Impact and Sustainability Concerns

While bio-based materials offer clear environmental advantages, comprehensive sustainability requires addressing:- Land use competition with food production- Water footprint of feedstock cultivation- Energy intensity of conversion processesCutting-edge approaches focus on:- Utilizing marginal lands for drought-resistant crops- Developing water-efficient fermentation technologies- Implementing carbon-negative production methodsLifecycle analyses now incorporate social and ecological factors beyond simple carbon accounting, providing more holistic sustainability assessments.

Overcoming Challenges in Material Properties and Performance

Material scientists are pioneering innovative solutions to performance gaps:- Nanocellulose reinforcements for mechanical strength- Bio-based plasticizers for improved flexibility- Hybrid composites combining multiple biopolymersStandardization efforts have resulted in:- ASTM test methods for biopolymer characterization- ISO certifications for industrial applications- Performance benchmarks across temperature rangesThe next generation of engineered bio-materials shows promise in matching or exceeding conventional material performance in targeted applications, particularly where specialized properties like biocompatibility or controlled degradation are required.