The Growing Demand for Biodegradable Plastics

The Environmental Urgency

Global awareness about plastic pollution has reached unprecedented levels, sparking intense interest in biodegradable alternatives. Traditional plastics linger in ecosystems for centuries, choking marine life and leaching toxins into soil and water. The scale of this crisis becomes clearer when considering that over 300 million tons of plastic waste are generated annually worldwide. Coastal communities witness firsthand the devastating effects, with beaches littered and fisheries contaminated. This unfolding disaster demands materials that disappear harmlessly after use.

Municipal waste systems groan under the weight of disposable packaging and single-use items. Landfills overflow while recycling programs struggle with contamination issues. The solution lies in materials designed to break down naturally, returning to the earth without leaving microplastic traces. Forward-thinking nations now mandate compostable packaging, creating regulatory pressure that accelerates adoption.

Economic Incentives and Market Growth

Environmental consciousness meets profit potential in the bioplastics sector. Analysts project the market will surpass $25 billion by 2026, with compound annual growth rates exceeding 15%. Major corporations now compete to secure sustainable packaging solutions, fearing consumer backlash against polluting alternatives. Venture capital floods into startups developing innovative biomaterials, while established chemical giants retool factories for bio-based production.

Shoppers increasingly vote with their wallets, choosing products in plant-based wrappers over conventional plastic. Retail giants respond by setting ambitious sustainability targets, creating guaranteed markets for compostable alternatives. This virtuous cycle attracts manufacturing investment and drives down production costs through economies of scale.

Technological Breakthroughs Driving Change

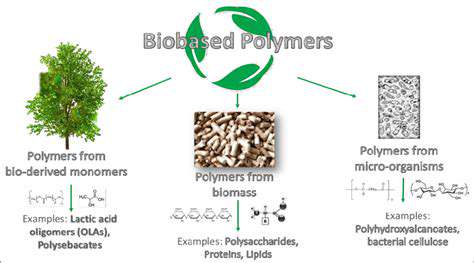

Cutting-edge research transforms agricultural waste into high-performance polymers. Scientists engineer microorganisms to produce PHA (polyhydroxyalkanoates) from food scraps, while others develop starch-based composites with strength rivaling petroleum plastics. Novel enzymatic processes now create biodegradable films that decompose in backyard compost heaps within weeks. Military and aerospace applications demonstrate these materials can meet extreme performance demands.

The production cost gap narrows as fermentation technologies improve yield efficiency. Pilot plants demonstrate commercial-scale manufacturing of PLA (polylactic acid) from non-food biomass. These advancements make biodegradable options cost-competitive with conventional plastics for many applications.

Diverse Industrial Applications

From surgical sutures that dissolve after healing to agricultural mulch films that enrich soil as they degrade, bioplastics demonstrate remarkable versatility. The food service industry leads adoption, replacing disposable cutlery and takeout containers with compostable versions. Textile innovators weave biodegradable fibers into temporary clothing for fast-fashion alternatives.

Packaging engineers design protective bioplastic foams for shipping delicate electronics. Automakers incorporate plant-based composites into interior panels. This breadth of application showcases the material's potential to transform multiple industries simultaneously.

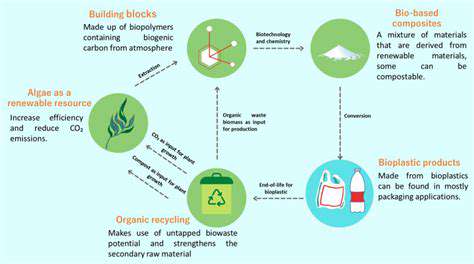

Bio-based Polymers and their Environmental Advantages

Renewable Feedstock Sources

Agricultural byproducts once considered waste now form the foundation of sustainable polymers. Rice husks, coconut shells, and pineapple leaves yield surprisingly durable bioplastics when processed with advanced techniques. Algae farms on non-arable land produce polymer precursors while sequestering carbon dioxide. These innovations reduce competition with food crops while utilizing marginal land resources.

Eco-Conscious Manufacturing

Modern biorefineries integrate polymer production with zero-waste principles. Enzymatic catalysis operates at lower temperatures than petrochemical processes, slashing energy requirements. Closed-loop water systems and biogas capture turn potential pollutants into valuable byproducts. Life cycle analyses confirm these methods can reduce carbon footprints by 60-80% compared to conventional plastics.

Performance Tailored to Purpose

Material scientists engineer polymer chains to achieve specific degradation rates and mechanical properties. Some formulations remain stable for years before rapidly breaking down when exposed to composting conditions. Medical-grade biopolymers now match the performance of traditional implants while eliminating removal surgeries. Packaging films combine barrier protection with predictable compostability timelines.

Carbon-Neutral Lifecycle

The photosynthesis that grows polymer feedstocks offsets emissions from manufacturing and transportation. Industrial composting facilities convert used bioplastics into nutrient-rich soil amendments, completing the carbon cycle. Marine-degradable formulations prevent ocean accumulation when accidental littering occurs. These closed-loop systems demonstrate how materials can harmonize with natural ecosystems.

Overcoming Commercial Hurdles

Standardization efforts address quality consistency concerns that initially deterred manufacturers. Strategic partnerships between farmers, processors, and end-users create reliable supply chains. Deposit-return schemes for biodegradable packaging improve collection rates for proper disposal. These systemic solutions address the chicken-and-egg challenges of scaling new materials.

Policy-Driven Market Transformation

Carbon pricing mechanisms increasingly favor bio-based alternatives. Extended producer responsibility laws now include preferential treatment for certified compostable packaging. Government procurement policies prioritize sustainable materials, creating stable demand that justifies production expansion. This policy landscape accelerates the transition from niche novelty to mainstream solution.