Technological Breakthroughs

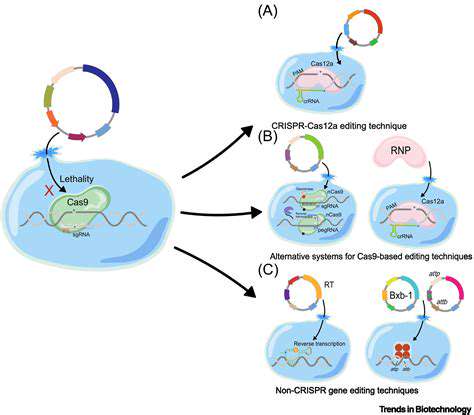

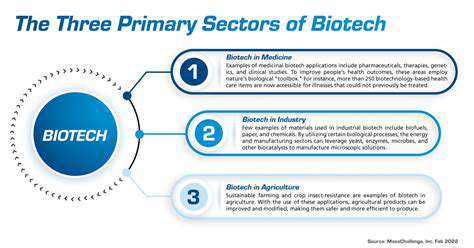

The science behind bio-production is advancing at breakneck speed. Genetic tweaks that once took years now happen in months, thanks to CRISPR and other gene-editing tools. Researchers are creating microbial factories that outperform traditional chemical processes in both efficiency and output quality. One lab recently engineered bacteria that can spin spider silk—a material stronger than steel—from plant sugars.

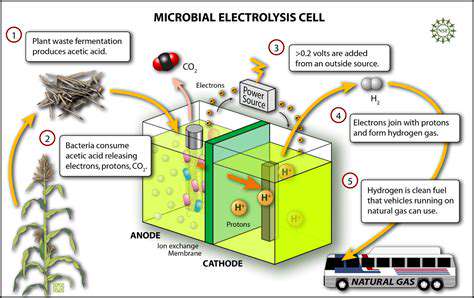

Processing innovations are equally transformative. New bioreactors operate with the precision of Swiss watches, while enzyme cocktails break down biomass with unprecedented efficiency. These advancements aren't just lab curiosities—they're reshaping cost equations, making bio-alternatives competitive with petroleum products. The implications extend far beyond niche markets, promising mainstream adoption across manufacturing sectors.

Economic Transformation

This isn't just an environmental story—it's an economic revolution. Traditional farming regions are reinventing themselves as bioeconomy hubs, while startups commercializing microbial technologies attract record venture funding. The job market reflects this shift, with bioprocess engineer becoming one of the fastest-growing STEM occupations.

Market dynamics tell the same story. Major retailers now mandate sustainable sourcing, creating guaranteed markets for bio-based materials. The financial sector has taken notice, with green bonds for bio-projects oversubscribed within hours of issuance. What began as environmental compliance is now driving shareholder value and creating competitive advantages for early movers.

Environmental Renaissance

The ecological benefits extend far beyond carbon metrics. A textile company using algae-based dyes reduced water consumption by 80% compared to conventional methods. Food packaging derived from agricultural waste decomposes in weeks rather than centuries. These aren't incremental improvements—they're complete reimaginings of industrial processes.

Perhaps most importantly, bio-production creates virtuous cycles. Waste from one process becomes raw material for another, mimicking nature's zero-waste systems. This systemic approach addresses environmental challenges at their root rather than just treating symptoms. As scaling continues, these solutions could help reverse decades of ecological damage while meeting growing material demands.

Engineered Microorganisms for Enhanced Efficiency

Harnessing Microbial Power

Custom-designed microbes represent biology's answer to 3D printing—programmable, adaptable, and endlessly customizable. These microscopic workhorses now produce everything from life-saving drugs to construction materials. One startup trains bacteria to extract rare earth elements from electronic waste, solving both resource scarcity and recycling challenges simultaneously.

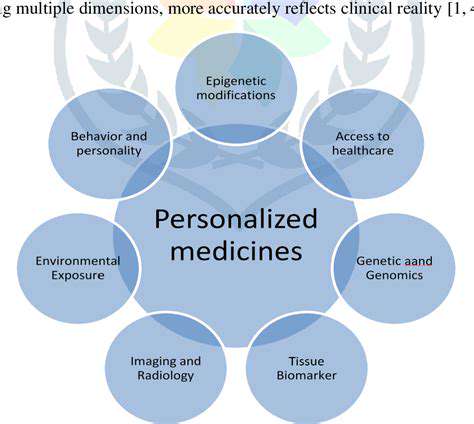

The precision possible today would astonish researchers from just a decade ago. Scientists can now edit microbial genomes with single-base accuracy, creating strains that convert waste gases into biodegradable plastics. This isn't just evolution—it's biological manufacturing with design intent. The implications span from pharmaceuticals (customized cancer treatments) to agriculture (nitrogen-fixing microbes that reduce fertilizer needs).

Metabolic Mastery

Modern metabolic engineering resembles conducting a symphony—every enzyme and pathway perfectly coordinated. Researchers recently redesigned yeast metabolism to produce morphine precursors without poppies, demonstrating both the power and ethical complexities of this field. The same principles help microbes convert CO2 into jet fuel, addressing aviation's sustainability challenges.

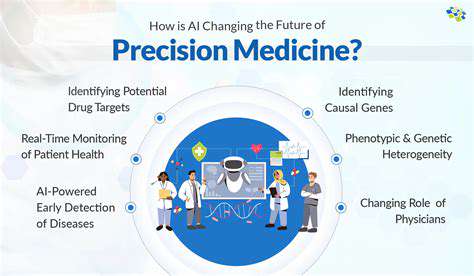

These advances rely on cutting-edge tools: machine learning predicts optimal genetic edits, while microfluidics allows testing thousands of microbial variants simultaneously. The result? Development cycles that once took years now occur in months. This acceleration is democratizing access, with cloud labs enabling researchers worldwide to design and test microbial strains remotely.

Cross-Industry Impact

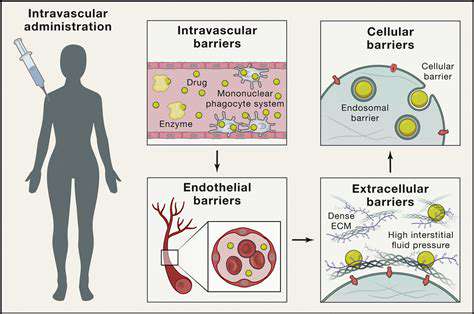

The applications read like science fiction made real: bacteria that weave carbon nanotubes for electronics, algae producing custom proteins for cultured meats, fungi creating self-healing concrete. In healthcare, engineered microbes now diagnose diseases from within the human gut and deliver targeted therapies.

Environmental applications are equally groundbreaking. Specialized bacteria digest oil spills while others capture methane from landfills. Perhaps most remarkably, microbial miners now extract copper and gold from low-grade ores with minimal environmental impact. These aren't future possibilities—they're commercial realities today, transforming industries from mining to waste management.

The food sector benefits enormously. Precision-fermented proteins now match animal-derived versions in taste and nutrition, while microbial enzymes reduce food waste by extending freshness. One company uses engineered yeast to produce vanilla flavoring identical to the natural compound—without vanilla orchids.

The Future of Manufacturing: A Symbiotic Relationship

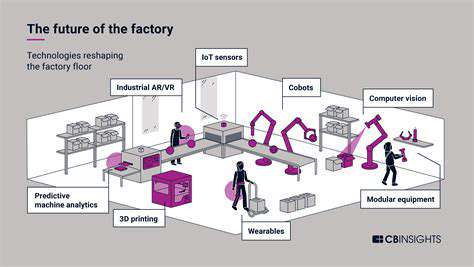

Intelligent Automation

Today's smart factories resemble living organisms more than mechanical systems. Self-optimizing production lines adjust in real-time based on supply chain data, quality metrics, and even weather patterns. Collaborative robots work alongside humans, learning from each interaction. One automotive plant reduced defects by 40% after implementing AI vision systems that spot imperfections invisible to the human eye.

The data revolution transforms maintenance from reactive to predictive. Vibration sensors and thermal imaging detect equipment issues weeks before failure, while digital twins simulate entire production runs before physical manufacturing begins. This isn't just efficiency—it's manufacturing clairvoyance.

Circular Systems

Forward-thinking manufacturers now design products for multiple lifecycles from inception. A leading electronics company recovers 98% of materials from returned devices, feeding them directly back into production. This closed-loop thinking turns waste streams into revenue streams while future-proofing against resource scarcity.

Energy strategies mirror this circularity. Factories integrate onsite renewables with smart grids, sometimes becoming net energy producers. One textile mill powers its operations entirely from biogas generated by processing wastewater—a system that pays for itself in under three years.

Human-Machine Collaboration

The workforce transformation is profound but often misunderstood. While robots handle repetitive tasks, human roles evolve toward system design, exception handling, and creative problem-solving. Modern manufacturing careers increasingly blend technical skills with design thinking and data literacy. Apprenticeship programs now include augmented reality training, allowing workers to master complex equipment virtually before touching physical machines.

This symbiosis creates safer, more engaging workplaces. Exoskeletons prevent injuries in material handling, while AR interfaces provide real-time guidance during complex assemblies. The result? Higher productivity paired with improved job satisfaction—a rare win-win in industrial history.

Agile Globalization

The pandemic exposed vulnerabilities in extended supply chains, prompting a strategic shift. Smart manufacturers now combine global scale with local resilience through distributed microfactories. 3D printing hubs near major markets enable rapid customization while reducing shipping needs. Digital platforms connect these nodes into responsive networks that reroute production dynamically.

This new model values flexibility over pure cost optimization. Some automakers now redesign vehicles around available components rather than waiting for delayed shipments. Others use blockchain to create transparent, ethical supply chains that consumers can verify in real-time. The future belongs to manufacturers who blend global reach with local adaptability.