Engineering Microbial Factories for Chemical Synthesis

Harnessing the Power of Metabolic Engineering

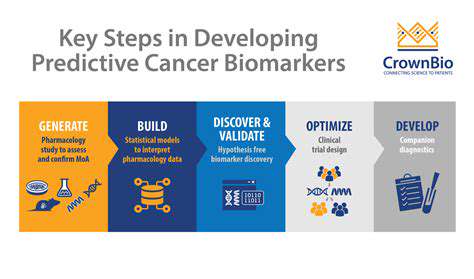

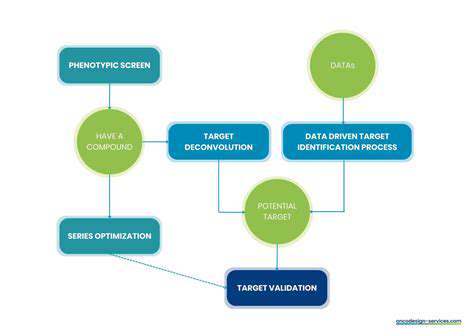

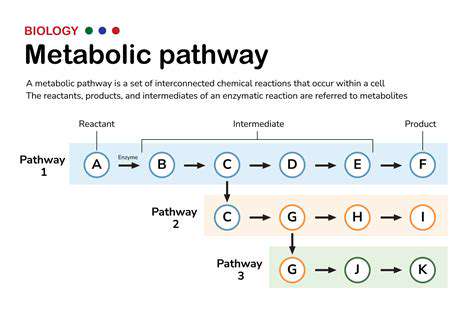

Metabolic engineering, a cornerstone of synthetic biology, allows scientists to re-program the metabolic pathways of microorganisms. This involves strategically modifying existing pathways or introducing entirely new ones, enabling the production of valuable chemicals. Optimizing cellular processes is key to achieving high yields with minimal waste. Understanding and manipulating these pathways is crucial to the development of sustainable industrial processes.

By decoding the complex biochemical reactions within microbes, researchers can identify bottlenecks and tweak key enzymes to boost output. Fine-tuning cellular machinery is what makes microbial factories truly effective for chemical production.

Designing Robust and Efficient Microbial Strains

Creating hardy microbial strains is essential for synthetic biology applications. These strains must endure environmental stresses like temperature swings, pH changes, and nutrient limitations. Genetic enhancements often include adding stress-response mechanisms and refining nutrient absorption pathways.

Additional modifications can improve strain stability and productivity. This might involve increasing target gene expression, reducing unwanted byproducts, and maximizing chemical yields. Thoughtful strain design forms the backbone of reliable microbial factories.

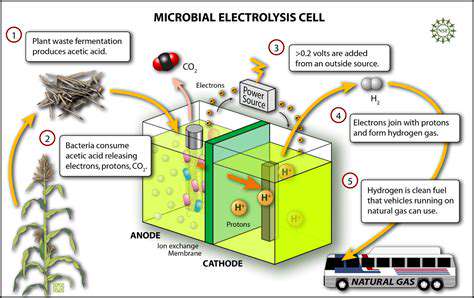

Optimizing Bioreactor Conditions for Enhanced Production

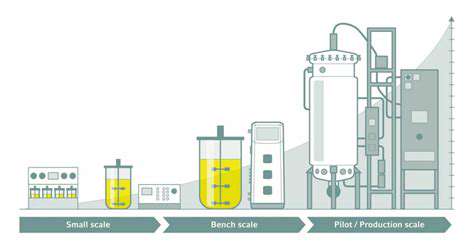

Bioreactors serve as the production hubs for microbial fermentation. Maintaining ideal conditions - temperature, pH, oxygen levels, and nutrients - is critical for achieving high cell densities and optimal yields. Precise control of these parameters ensures efficient operation.

Advanced bioreactor designs incorporating real-time sensors and automated controls can significantly improve fermentation precision. These optimizations are vital for boosting factory performance and sustainability.

Developing Novel Genetic Tools and Strategies

Innovative genetic tools expand metabolic engineering possibilities. Advanced CRISPR-Cas systems enable precise genome editing, while synthetic promoters allow controlled gene expression. Such tools provide exact control over metabolic pathways, leading to more efficient production.

New genetic circuits and regulatory systems further customize microbial factories. These advancements enable tailored responses to environmental conditions and precise chemical synthesis control. Ongoing research in this area continues to push synthetic biology forward.

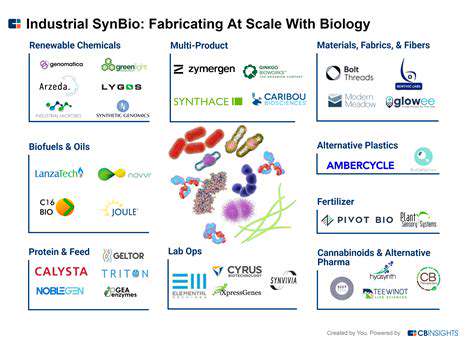

Exploring Diverse Microbial Species for Specific Applications

Microbial diversity offers unique metabolic capabilities for specialized chemical production. From bacteria and archaea to algae and fungi, each organism presents distinct metabolic profiles that can be harnessed for specific synthesis tasks.

Addressing Environmental Sustainability Concerns

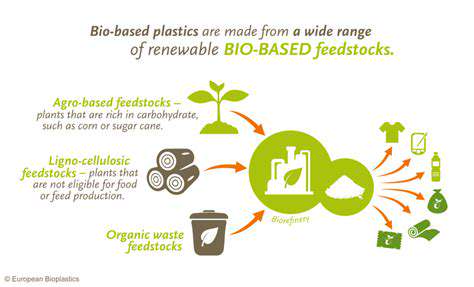

Sustainability is fundamental in microbial factory development. Using renewable feedstocks, reducing waste, and optimizing energy use are critical for sustainable industry. Genetically modified microbes also show promise for environmental cleanup applications.

Sustainable practices must encompass the entire production lifecycle, from raw materials to final product disposal. This comprehensive approach ensures long-term viability for this emerging technology.

Integrating Biomanufacturing into Existing Industrial Processes

Successful implementation requires smooth integration with current industrial systems. This involves scaling up production efficiently, refining downstream processing, and ensuring economic feasibility. Adapting existing infrastructure and developing new purification methods are often necessary.

Collaboration between biologists, engineers, and industry partners is essential to overcome technical challenges and achieve large-scale adoption. This teamwork will ultimately determine the technology's real-world impact.

Challenges and Future Directions

Scaling Production and Cost-Effectiveness

A major challenge is scaling up to meet industrial demands. Lab-scale processes often fail to translate effectively to large operations, increasing costs and complexity. Developing high-throughput biomanufacturing platforms is crucial for competing with petrochemical processes.

Refining downstream processing, including purification methods, is equally important. Developing eco-friendly separation techniques can reduce costs and environmental impact. Alternative methods like membrane filtration show particular promise.

Addressing Environmental Concerns and Sustainability

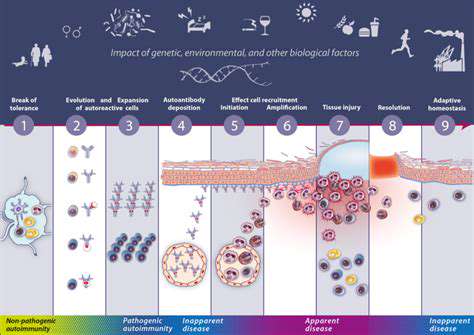

While promising, synthetic biology requires careful environmental consideration. Using GMOs raises ecological concerns that demand thorough risk assessment. Understanding potential gene flow and ecosystem impacts is essential before large-scale deployment.

Reducing the production process's environmental footprint is equally critical. This means conserving water and energy, minimizing waste, and choosing sustainable feedstocks. Closed-loop systems that repurpose byproducts can dramatically improve sustainability.

Ethical Considerations and Public Perception

Ethical issues and public acceptance play crucial roles in technology adoption. Clear communication about synthetic biology's benefits and risks is essential for building trust. Ongoing dialogue between scientists, policymakers, and the public helps navigate ethical concerns.

Ensuring equitable access to benefits and preventing resource disparities is equally important. Responsible innovation through robust safety measures and transparent regulation is key to realizing synthetic biology's potential while minimizing risks.