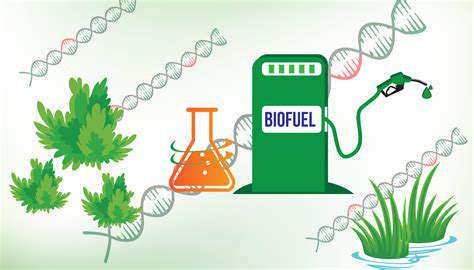

Introduction to Synthetic Biology and Biofuels

Defining Synthetic Biology

Synthetic biology, a rapidly evolving field, encompasses the design and construction of new biological parts, devices, and systems, or the re-design of existing, natural biological systems for useful purposes. This interdisciplinary field draws from engineering principles to manipulate biological systems, aiming to create novel functionalities not found in nature. It leverages our understanding of molecular biology, genetics, and engineering to build and program living organisms in a controlled manner, offering exciting potential for addressing global challenges.

The core concept revolves around understanding the fundamental building blocks of life – genes, proteins, and metabolic pathways – and then assembling them in novel ways. This precise control over biological processes allows for the creation of organisms with tailored characteristics, surpassing what natural evolution can achieve. This ability to engineer biological systems has profound implications for various fields, from medicine and agriculture to energy and environmental remediation.

Applications of Synthetic Biology

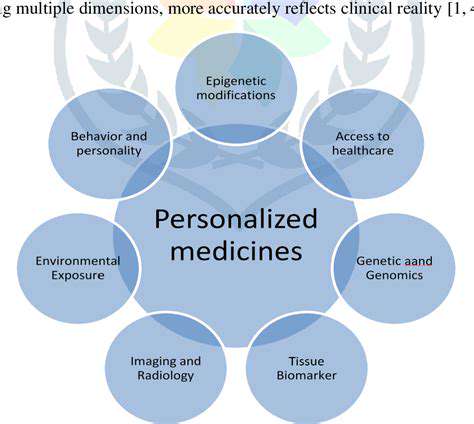

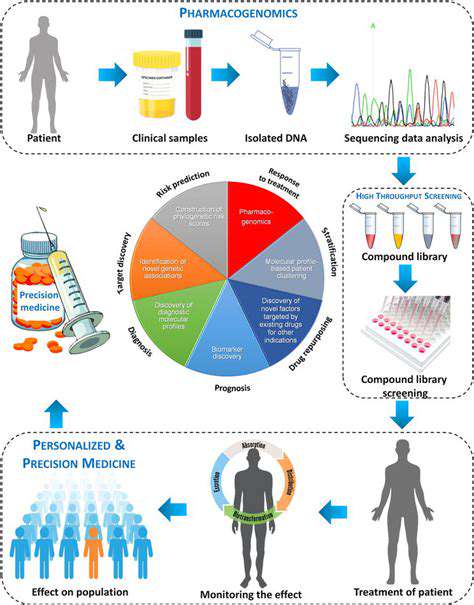

Applications of synthetic biology are diverse and impactful. One prominent application lies in the realm of medicine, where synthetic biology is used to develop new therapies and diagnostic tools. For instance, researchers are employing synthetic biology to create novel vaccines, targeted drug delivery systems, and biosensors for early disease detection. This precision engineering approach promises to revolutionize personalized medicine, offering treatments tailored to individual patient needs.

Another significant area of application involves agriculture. Synthetic biology is being explored to enhance crop yields, improve nutritional content, and engineer plants resistant to pests and diseases. By modifying the genetic makeup of plants, synthetic biologists aim to develop more sustainable and resilient agricultural practices, contributing to global food security.

The Ethical Considerations of Synthetic Biology

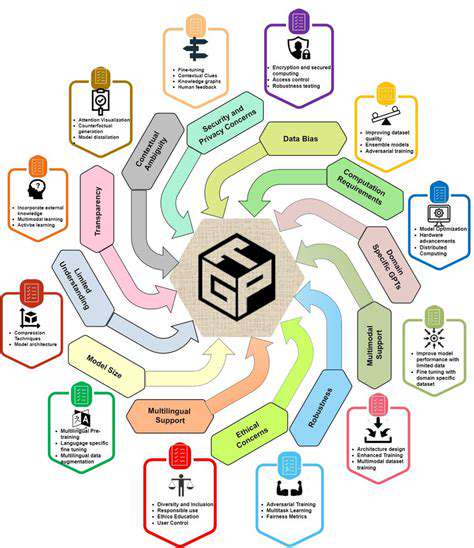

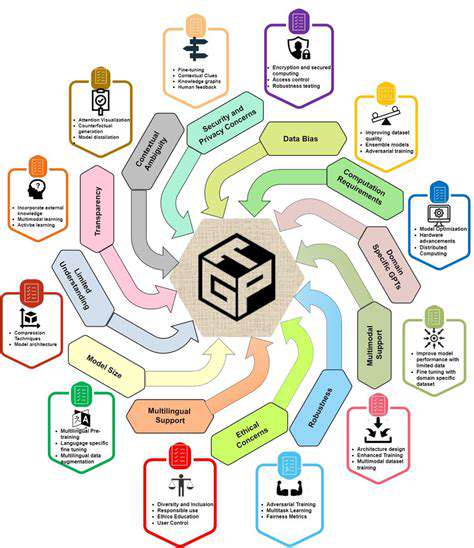

As synthetic biology advances, it's crucial to acknowledge and address the associated ethical considerations. The ability to manipulate life raises questions about the potential for unintended consequences and misuse. Careful consideration and robust ethical frameworks are essential to ensure responsible development and application of this powerful technology. Public engagement and transparent dialogue are vital to fostering trust and addressing concerns surrounding the long-term impacts of synthetic biology.

Furthermore, questions arise regarding intellectual property rights, access to technology, and equitable distribution of benefits. These considerations require international collaboration and ethical guidelines to ensure that the benefits of synthetic biology are shared broadly and its risks are mitigated effectively. We must navigate these complexities with careful consideration for the well-being of both human societies and the environment.

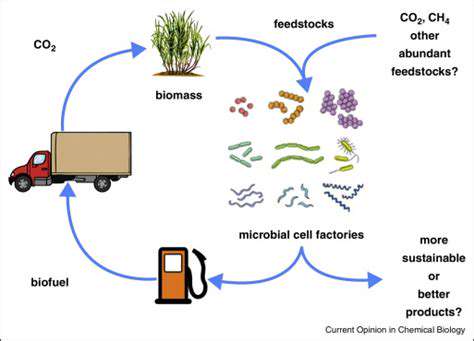

Harnessing Microbes for Biofuel Conversion

Harnessing the Power of Microbial Communities

Microbes, encompassing bacteria, archaea, and fungi, play a crucial role in biofuel production. Their metabolic capabilities are remarkably diverse, allowing them to break down complex organic matter into simpler compounds, which can then be further processed into biofuels. Understanding and manipulating these microbial communities is key to optimizing biofuel conversion processes, leading to increased yields and reduced costs.

Harnessing the collective power of these microbial communities, rather than relying on individual organisms, often leads to more efficient and robust biofuel production systems. The synergistic interactions within these microbial communities can enhance the degradation of complex substrates, thereby maximizing the conversion efficiency.

Genetic Engineering of Microbes for Enhanced Performance

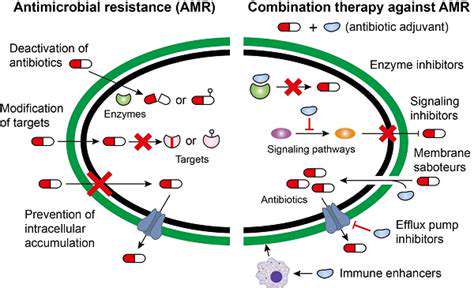

Synthetic biology techniques provide a powerful toolkit to engineer microbes for enhanced biofuel production. This involves modifying the microbes' genetic makeup to improve their ability to utilize specific feedstocks, produce target biofuels, and enhance tolerance to unfavorable conditions. For instance, we can introduce genes that encode for enzymes capable of breaking down recalcitrant biomass or increase the production of valuable biofuel precursors.

By employing gene editing technologies like CRISPR-Cas9, scientists can precisely modify microbial genomes, leading to more efficient and targeted improvements in their biofuel production capabilities. This approach allows for the creation of highly specialized microbial strains optimized for specific biofuel pathways.

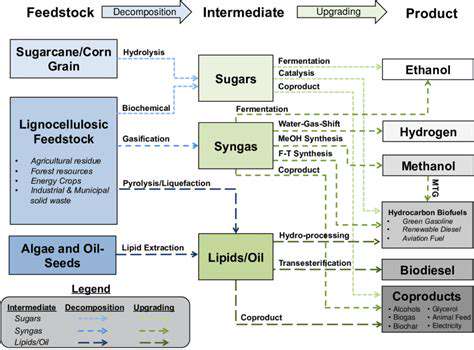

Optimizing Feedstock Utilization for Microbial Growth

The type and quality of feedstocks significantly impact the efficiency of microbial biofuel conversion. Effective strategies for optimizing feedstock utilization involve pre-treatments to enhance the accessibility of complex carbohydrates and lignocellulosic biomass, making them more readily available to microbial enzymes. This pre-treatment step is crucial in maximizing the conversion efficiency of the feedstock into biofuel.

Careful selection and pre-treatment of feedstocks can greatly influence the growth of specific microbial communities, leading to higher biofuel yields. This includes using agricultural residues, industrial waste, or even algae as feedstocks, ensuring that the chosen feedstock is both cost-effective and environmentally sustainable.

Developing Novel Bioreactor Designs for Enhanced Efficiency

Bioreactor design plays a critical role in maximizing microbial biofuel production. Innovative bioreactor designs should be optimized for efficient mixing, oxygen transfer, and temperature control, which are essential parameters for optimal microbial growth and biofuel production. Effective bioreactor configurations can improve the overall productivity and reduce the cost of biofuel production.

Improving Microbial Tolerance to Environmental Stress

Microbes can be challenged by various environmental stresses, such as fluctuations in temperature, pH, and nutrient availability, which can negatively impact biofuel production. Developing microbial strains with enhanced tolerance to these stresses is crucial for maintaining high conversion rates under diverse conditions. This also involves the development of robust and cost-effective cultivation methods.

Scaling Up Biofuel Production for Commercial Viability

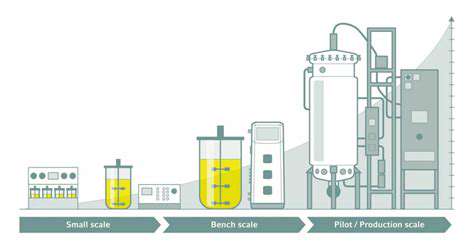

Transitioning from laboratory-scale biofuel production to large-scale commercial operations requires careful consideration of various factors, including process optimization, cost-effectiveness, and scalability. Developing efficient downstream processing strategies for separating and purifying the produced biofuels is a major challenge. The key to commercial viability lies in finding a balance between high production rates, low production costs, and environmental sustainability.

Monitoring and Controlling Microbial Processes for Quality Assurance

Implementing robust monitoring and control systems is essential for ensuring consistent quality and yield in microbial biofuel production. This involves continuously monitoring parameters such as microbial growth, substrate consumption, and product formation. Real-time data analysis and process adjustments can help maximize productivity and minimize process inefficiencies. Careful monitoring is vital for maintaining the desired quality standards and preventing contamination.

Developing Robust and Cost-Effective Production Systems

Optimizing Production Processes

A key aspect of developing robust and cost-effective production systems is optimizing the processes themselves. This involves meticulous analysis of each step, from raw material acquisition to final product packaging. By identifying bottlenecks and inefficiencies, significant improvements in yield, productivity, and overall cost reduction can be achieved. This optimization should consider the specific needs of the production environment, taking into account factors such as available resources, regulatory compliance, and environmental impact. Careful consideration of these factors leads to a more sustainable and profitable production model.

Harnessing Synthetic Biology Tools

Synthetic biology provides a powerful toolkit for streamlining production processes. By engineering microorganisms or other biological systems, we can create highly efficient catalysts, bioreactors, and pathways for producing desired products. These engineered systems can be optimized for specific conditions, leading to enhanced yield and reduced production costs. The ability to precisely control biological processes through synthetic biology opens up opportunities for creating bespoke solutions tailored to specific production needs.

Reducing Material Waste

Minimizing waste is crucial for cost-effectiveness and sustainability in production. Synthetic biology can play a vital role in this aspect by designing organisms capable of efficiently utilizing resources, reducing the amount of byproducts, and maximizing the yield of desired products. This approach not only saves money but also minimizes the environmental footprint of the production process. Waste reduction is a key element of a sustainable and economically viable production system.

Improving Efficiency through Strain Engineering

Strain engineering is a powerful technique within synthetic biology that allows for the creation of microorganisms with enhanced traits. These traits might include higher production rates, improved substrate utilization, or resistance to environmental stressors. By manipulating genetic material, we can tailor microorganisms to perform specific tasks within the production system, thus maximizing efficiency and reducing production time. This targeted approach to strain engineering is crucial for developing robust and cost-effective production systems.

Scalability and Reproducibility of Production

A robust production system must be scalable and reproducible. The design of the production process should account for potential increases in demand or the need for replicating the system across different locations. Synthetic biology designs can be adapted to accommodate larger-scale production with minimal modifications. Maintaining consistent quality and yield across various production runs is essential, ensuring reliability and efficiency in the long term.

Addressing Cost Considerations in Production

Cost-effectiveness is paramount in industrial production. Synthetic biology can be instrumental in reducing production costs by optimizing resource utilization and minimizing waste. The development of bio-based processes, tailored to specific products, can potentially replace costly chemical processes. Careful consideration of factors like raw material costs, energy consumption, and labor requirements is crucial for achieving the desired cost-effectiveness in the production process. This is particularly relevant for the creation of sustainable production solutions.

Ensuring Environmental Sustainability

Environmental sustainability is increasingly important in modern production. Synthetic biology offers a powerful approach to designing bio-based processes that minimize environmental impact. By leveraging renewable resources and reducing waste generation, we can create more environmentally friendly production systems. This approach not only protects the environment but also aligns with growing consumer demand for sustainable products and processes. The ecological footprint of a production system is therefore a key factor to consider and minimize.