Improving Biofuel Production through Microbial Engineering

Harnessing Microbial Diversity

Microbial communities, encompassing bacteria, fungi, and archaea, play a crucial role in biofuel production. A deeper understanding of the diverse metabolic pathways and genetic capabilities within these communities is essential for optimizing biofuel yields. Researchers are actively exploring the genetic diversity of microorganisms, identifying novel enzymes and pathways that can efficiently convert various feedstocks into biofuels. This exploration of microbial diversity is a critical step in developing robust and sustainable biofuel production systems.

Utilizing extremophiles, microorganisms thriving in extreme environments like high temperatures, high salinity, or acidic conditions, offers potential advantages. These organisms often possess unique enzymes with enhanced stability and activity under challenging conditions, which could prove invaluable in industrial biofuel production processes. Harnessing this untapped potential through genetic engineering and metabolic pathway optimization could lead to significant advancements in biofuel production efficiency.

Optimizing Metabolic Pathways

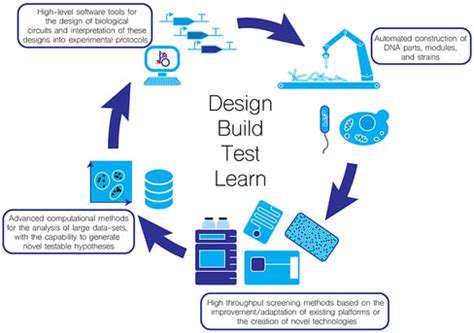

Metabolic engineering aims to modify the existing metabolic pathways of microorganisms to enhance their biofuel production capabilities. This involves identifying and manipulating key genes and enzymes involved in the conversion of biomass into biofuel precursors. By altering the expression levels of these genes, researchers can effectively redirect the metabolic flow towards biofuel production, increasing the overall efficiency of the process.

Strategies like pathway optimization and synthetic biology hold immense promise. Pathway optimization involves fine-tuning the existing metabolic pathways to maximize biofuel production. Synthetic biology, on the other hand, involves creating entirely new metabolic pathways or incorporating genes from other organisms to enhance the production of desired biofuels. The development of robust and efficient biofuel production systems depends heavily on the effectiveness of these strategies.

Enhancing Feedstock Utilization

The choice of feedstock significantly impacts the overall efficiency and sustainability of biofuel production. Developing strategies for utilizing diverse and readily available feedstocks, such as agricultural residues, algae, or even waste materials, is crucial for minimizing environmental impact and maximizing resource utilization. Microbial engineering can play a critical role in adapting microbial organisms to utilize these different feedstocks, thereby expanding the range of sustainable sources for biofuel production.

Furthermore, improving the efficiency of biomass pretreatment methods can significantly enhance the accessibility of complex molecules within the feedstock, making them more readily available for microbial conversion. This approach not only increases the overall yield of biofuel but also minimizes the energy requirements for the entire process, leading to a more sustainable and cost-effective biofuel production system.

Sustainable Biomaterial Production from Plant-Based Resources

Harnessing the Power of Plant-Based Resources

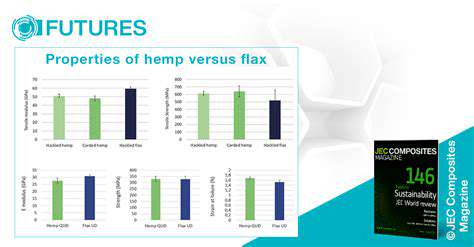

Sustainable biomaterial production hinges on effectively utilizing plant-based resources, a crucial aspect of biotechnological innovation. Exploring the diverse range of plant materials, from agricultural byproducts to dedicated energy crops, offers a wealth of potential feedstocks for biomaterial synthesis. This approach significantly reduces reliance on fossil fuels and promotes a circular economy model, minimizing environmental impact while maximizing resource efficiency. Understanding the inherent properties and chemical compositions of various plant sources is paramount for optimizing biomaterial production and ensuring their suitability for specific applications.

The inherent diversity of plant-based resources provides a vast array of potential building blocks for biomaterials. From the cellulose-rich fibers of wood to the starch-rich components of various tubers and grains, each plant offers a unique profile of chemical compounds. A detailed understanding of these compositional variations is essential for tailoring biomaterial production to specific requirements, ensuring the optimal extraction and processing of valuable components for downstream applications.

Optimizing Extraction and Processing Techniques

Efficient extraction and processing of valuable components from plant resources are critical for maximizing the yield and quality of biomaterials. Advanced biotechnological approaches, including enzymatic hydrolysis and solvent extraction, are crucial for effectively separating desired biopolymers from other plant constituents. Careful consideration of processing conditions, such as temperature, pressure, and pH, is essential to prevent degradation of the target biomolecules and maintain their structural integrity.

Novel extraction techniques, such as supercritical fluid extraction and microwave-assisted extraction, are being developed to enhance efficiency and selectivity. These advancements are crucial for minimizing the energy consumption and environmental footprint of biomaterial production while maximizing the recovery of valuable biopolymers from plant sources. Optimizing these processes is key to realizing the full potential of plant-based biomaterials.

Bioconversion Strategies for Enhanced Functionality

Bioconversion strategies play a pivotal role in enhancing the functionality and properties of plant-derived biomaterials. Enzymatic modifications, for example, can alter the molecular structure of biopolymers to create tailored properties, such as improved strength, biodegradability, or specific functionalities. This approach can significantly enhance the applications of biomaterials in various sectors, including packaging, textiles, and construction.

Further enhancements can be achieved through genetic engineering of plants, enabling the production of biomaterials with enhanced traits. These genetically modified organisms (GMOs) can be tailored to produce biopolymers with improved properties, potentially leading to superior biomaterials for applications such as biomedical devices or advanced composites.

Quality Control and Characterization

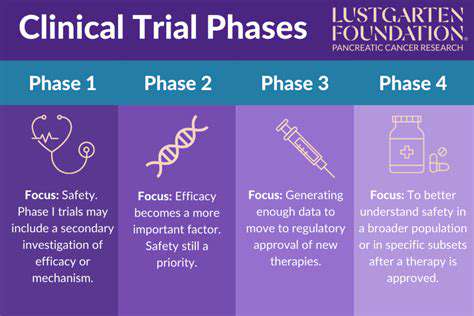

Rigorous quality control and comprehensive characterization are indispensable aspects of sustainable biomaterial production. Precise analytical techniques, such as spectroscopy and chromatography, are vital for assessing the purity and structural integrity of biomaterials. These methods ensure that the products meet the desired specifications for various applications and guarantee consistent performance. Maintaining high standards of quality control throughout the entire production process is essential for ensuring the reliability and safety of biomaterials in diverse applications.

Strict adherence to quality control protocols is essential for meeting industry standards and consumer expectations. Thorough characterization of the biomaterials' chemical composition, mechanical properties, and biodegradability is crucial for assessing their suitability for various applications. This careful evaluation is vital for ensuring the safety and efficacy of plant-derived biomaterials in diverse applications.

Enhancing Biomass Conversion Efficiency

Optimizing Pretreatment Strategies

Pretreatment is a crucial step in biomass conversion, significantly impacting the subsequent enzymatic hydrolysis and overall efficiency. Effective pretreatment methods aim to break down the complex structure of plant biomass, making it more accessible to enzymes. This process often involves the use of chemicals, heat, or mechanical forces. The choice of pretreatment method depends on several factors, including the type of biomass being used and the desired level of conversion.

Different pretreatment techniques have varying degrees of effectiveness and environmental impact. For example, chemical pretreatments, while often achieving high yields, can introduce undesirable byproducts into the process. Mechanical pretreatments, on the other hand, generally result in fewer chemicals but may require more energy input. Careful consideration of both the economic and environmental aspects is vital when selecting the appropriate pretreatment method.

Improving Enzyme Activity and Stability

Enzymes play a critical role in the conversion of pretreated biomass into fermentable sugars. Optimizing enzyme activity and stability is therefore essential for maximizing the efficiency of the entire process. This involves careful selection of enzymes, considering factors such as their specificity for different types of biomass and their ability to function effectively under specific temperature and pH conditions.

Enzyme stability is also crucial. Exposure to extreme conditions during the hydrolysis process can lead to enzyme inactivation and reduced sugar yields. The use of enzyme immobilization techniques can help to increase their stability and reusability, ultimately reducing costs and improving the overall process efficiency.

Furthermore, optimizing enzyme loading and reaction conditions, such as temperature and pH, is critical to maximizing the rate and extent of hydrolysis. This requires careful laboratory experiments to determine the optimal conditions for each specific enzyme and biomass combination.

Developing Advanced Bioreactor Designs

Bioreactor design significantly influences the efficiency of biomass conversion. Advanced bioreactor designs are essential to ensure optimal conditions for enzymatic hydrolysis and subsequent fermentation. These designs should consider factors like mixing, temperature control, and substrate delivery, all of which directly impact the rate and yield of the process. The design should be tailored to the specific characteristics of the biomass and the enzymes being used.

Implementing efficient heat management and gas exchange systems within the bioreactor is crucial to maintain optimal reaction conditions throughout the process. This is especially important to ensure that the enzymes operate at their peak efficiency and prevent unwanted byproducts from forming. The use of advanced monitoring and control systems can further enhance the process optimization and ensure consistent performance.

Optimizing downstream processing

The downstream processing steps, including product separation and purification, are equally important to the overall efficiency of biomass conversion. These steps involve the separation of the desired products, such as biofuels or bioproducts, from the remaining biomass and other components. Efficient separation methods are essential to obtain high-quality products. The choice of separation method will depend on the specific product being targeted.

Further optimization in this stage might involve the utilization of membrane filtration, adsorption, or other techniques to effectively purify the desired products. Careful consideration of the economic feasibility and environmental impact of these downstream processing steps is crucial to ensure a sustainable and profitable biomass conversion process.