Harnessing Nature's Catalysts

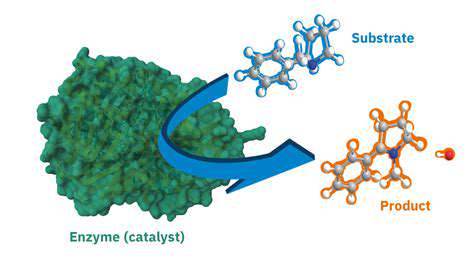

Biocatalysis, a field deeply rooted in the principles of chemistry and biology, leverages the remarkable power of enzymes as catalysts. These naturally occurring biological molecules accelerate chemical reactions under mild conditions, making them invaluable across industrial and research applications. Enzymes exhibit extreme specificity, often targeting single substrates to minimize byproducts and maximize efficiency. This precision enables cleaner, more sustainable processes - a critical advantage in modern environmentally conscious industries.

Unlike traditional chemical catalysts, enzymes function at remarkably low temperatures and pressures, dramatically reducing energy requirements. Their intricate three-dimensional structures create perfect molecular accommodations that facilitate reactions with unprecedented efficiency. This ability to perform complex transformations under gentle conditions revolutionizes applications from pharmaceuticals to food processing.

Enzymatic Applications Across Industries

Biocatalysis transforms multiple industrial sectors. Pharmaceutical manufacturers rely on enzymes to create complex chiral drug molecules. Their precise reaction control eliminates many tedious synthesis steps, streamlining drug production while reducing costs significantly.

The food and beverage industry benefits equally. Cheese production, starch hydrolysis, and winemaking all utilize enzymatic processes that enhance quality and efficiency. Enzymes break complex carbohydrates into fermentable sugars, enabling diverse fermented product creation.

Textile manufacturers employ enzymes for fabric cleaning and finishing, replacing harsh chemicals with biological alternatives that reduce environmental impact while improving product quality.

Advantages and Challenges of Enzyme-Based Processes

Biocatalytic methods outperform traditional chemical processes through milder conditions, superior selectivity, and reduced waste generation. Enzymatic specificity virtually eliminates unwanted side reactions, yielding purer products in greater quantities. These attributes make biocatalysis a cornerstone of sustainable industrial practices.

Practical challenges remain regarding enzyme stability and production costs in industrial settings. Developing robust enzymes capable of withstanding large-scale process conditions requires continued research. Similarly, creating cost-effective, scalable production methods remains crucial for widespread adoption. Despite these hurdles, biocatalysis holds transformative potential for industrial processes that continues driving significant scientific investment.

Effective content marketing transcends simple article creation or social media updates. It represents a strategic approach to engaging target audiences through valuable insights and solutions. Successful implementation demands deep understanding of audience pain points and content that directly addresses these concerns. When executed properly, this methodology builds trust and establishes brand authority.

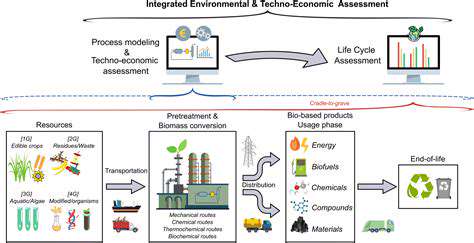

Bioprocess Optimization and Engineering for Maximum Efficiency

Improving Microbial Growth Kinetics

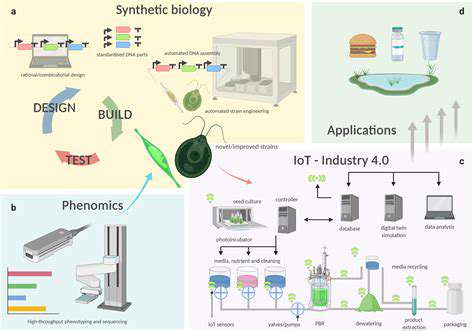

Optimizing bioprocess conditions for microbial growth significantly impacts bioproduct yields. Temperature, pH, and nutrient availability require precise control to achieve exponential growth phases. Careful growth curve monitoring, lag phase analysis, and strain-specific condition optimization create robust, reproducible processes. Detailed growth curve analysis identifies critical parameters and process bottlenecks, enabling targeted efficiency improvements.

Substrate Utilization and Metabolic Engineering

Optimal substrate concentration and feeding strategies minimize waste while maximizing product conversion. Metabolic engineering redirects microbial pathways toward target bioproducts through gene modification or regulatory manipulation. Engineered microorganisms demonstrate superior substrate conversion efficiency, substantially improving process yields.

Process Scale-Up and Downstream Processing

Industrial-scale bioprocessing presents unique challenges in maintaining efficiency and quality. Bioreactor design must ensure proper mass and oxygen transfer across scales. Understanding physical and chemical process interactions enables consistent performance during scale transitions, with careful attention to heat transfer and fluid dynamics.

Controlling Bioreactor Environment

Precise control of temperature, pH, and dissolved oxygen maximizes productivity while minimizing contamination. Automated monitoring systems maintain optimal conditions, ensuring stable microbial activity and consistent product quality. This environmental control proves essential for reliable, high-yield operations.

Cost-Effectiveness and Sustainability

Economic viability requires minimized resource consumption and waste generation. Sustainable practices throughout the production cycle, from material sourcing to waste management, ensure long-term feasibility. Environmental impact assessments guide continuous process improvements toward greater sustainability.