Optimizing Bioreactor Design and Operation for Enhanced Yields

Improving Substrate Utilization

Optimizing bioreactor design and operation is crucial for maximizing substrate utilization in bioprocesses. Effective mixing plays a pivotal role in ensuring uniform distribution of nutrients throughout the bioreactor, enabling all cells to access the necessary resources for growth and product synthesis. Properly sized agitators and impeller designs are essential to achieve efficient mixing without excessive shear stress, which can damage the delicate microbial cells. Furthermore, careful control of aeration is critical. Insufficient oxygen supply can limit cell growth, while excessive aeration can lead to foam formation and increased energy consumption.

The selection of appropriate culture conditions, including temperature, pH, and dissolved oxygen levels, is also paramount. Precise monitoring and control of these parameters are essential to maintain optimal growth conditions for the specific microorganism being cultivated. Furthermore, efficient removal of inhibitory byproducts or waste products is equally important. This may involve strategies like continuous extraction or specialized bioreactor configurations that facilitate the separation of unwanted substances.

Controlling Cell Growth and Product Formation

A key aspect of bioreactor optimization involves controlling cell growth kinetics and product formation. Understanding the specific growth requirements of the microorganisms, including lag phase, exponential growth phase, and stationary phase, is crucial for designing effective bioreactor operations. Adjusting the bioreactor parameters, such as nutrient concentration, temperature, and pH, during different growth phases can significantly enhance the yield of the desired product.

Furthermore, understanding the metabolic pathways involved in product formation is critical. Manipulating the bioreactor conditions to favor specific metabolic pathways, potentially by adding specific nutrients or modifying the environment, can lead to a higher yield and improved quality of the desired product. Careful monitoring of cell density and product concentration throughout the process is vital for tracking progress and making necessary adjustments to maintain optimal conditions.

Implementing strategies to minimize contamination during the bioreactor operation is also critical. This includes maintaining sterile conditions throughout the process, using appropriate sterilization protocols, and implementing robust monitoring and control systems to detect and eliminate any contamination risks. Maintaining a high level of hygiene within the bioreactor environment is essential for achieving high product purity.

Process Intensification and Scale-up Strategies

Bioreactor design and operation strategies should be readily scalable to meet industrial production needs. Process intensification techniques, such as using membrane bioreactors or immobilized cell systems, can offer enhanced productivity and resource efficiency. These strategies can lead to higher volumetric productivities and reduce the overall footprint of the bioreactor system. Scale-up considerations, such as maintaining similar mixing and mass transfer characteristics across different reactor sizes, are crucial for successful industrial implementation. Carefully designed scale-up strategies are essential to ensure that the optimized conditions developed in laboratory-scale bioreactors are transferable and successful in larger-scale operations, minimizing losses and maximizing efficiency.

Implementing robust control systems and predictive modeling tools is essential for ensuring stable and predictable bioreactor operation at different scales. These tools can help in adjusting and optimizing the bioreactor parameters in real-time, allowing for dynamic control of the process and preventing deviations from the desired performance parameters. This is crucial for optimizing the process and avoiding unexpected issues during scale-up.

Upstream and Downstream Processing: Mastering the Entire Production Chain

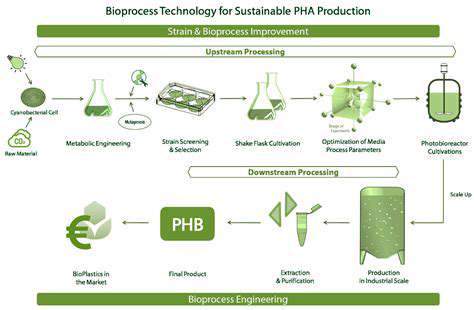

Upstream Processing: From Raw Materials to Initial Conversion

Upstream processing encompasses the initial stages of the production chain, focusing on acquiring and preparing raw materials. This crucial phase sets the foundation for the entire production process, impacting everything from product quality to overall efficiency. Careful selection of raw materials, adhering to strict quality control measures, and implementing sustainable practices are paramount to success in this stage. This involves meticulous sourcing, ensuring the materials meet the necessary specifications, and potentially undergoing preliminary treatments like cleaning, sorting, and pre-processing to optimize their suitability for subsequent downstream operations. Minimizing waste and maximizing yield in the upstream phase is critical for profitability and environmental responsibility.

Effective upstream processing also involves careful planning and risk management. Fluctuations in raw material availability, pricing, and quality can significantly impact the production schedule and costs. Therefore, establishing strong supply chains and diversification strategies are key to mitigating risks. Forecasting demand and adjusting production plans accordingly is also vital to maintain a smooth transition into downstream processing. In essence, upstream processing acts as the crucial link between the raw materials and the finished product, shaping the quality, cost, and sustainability of the entire production chain.

Downstream Processing: Transforming Raw Materials into Finished Goods

Downstream processing involves the series of steps that transform the prepared raw materials into the final, finished product. This stage often encompasses complex manufacturing processes, requiring specialized equipment, skilled labor, and meticulous quality control procedures. From assembly and packaging to testing and certification, each step must be executed with precision and adherence to strict standards to maintain product quality and consistency.

An important aspect of downstream processing is the optimization of production efficiency. Streamlining workflows, minimizing waste, and maximizing output are crucial for cost-effectiveness. Modern technologies like automation and robotics play a significant role in achieving these goals, enhancing speed and precision while reducing human error. Implementing robust quality control measures at each stage of the downstream process is essential to ensure that the final product meets the required specifications and customer expectations. This includes stringent testing, inspections, and adherence to quality assurance standards, minimizing defects and ensuring product reliability.

Furthermore, downstream processing plays a critical role in value addition. This involves enhancing the product's features, functionality, and overall appeal to the consumer. This could include intricate design enhancements, advanced technological integrations, or the addition of unique packaging. Ultimately, effective downstream processing ensures that the finished product meets market demands, satisfies consumer needs, and achieves desired profitability for the business. Successful completion of the downstream stage is the culmination of the entire production chain, ensuring customer satisfaction and the long-term success of the enterprise.

In today's interconnected world, Internet of Things (IoT) devices are increasingly vulnerable to a wide range of cyber threats. Malicious actors are constantly developing new and sophisticated techniques to exploit vulnerabilities in these devices, ranging from simple denial-of-service attacks to more sophisticated data breaches. Understanding the evolving threat landscape is crucial for implementing effective security measures and protecting sensitive data transmitted through these devices.