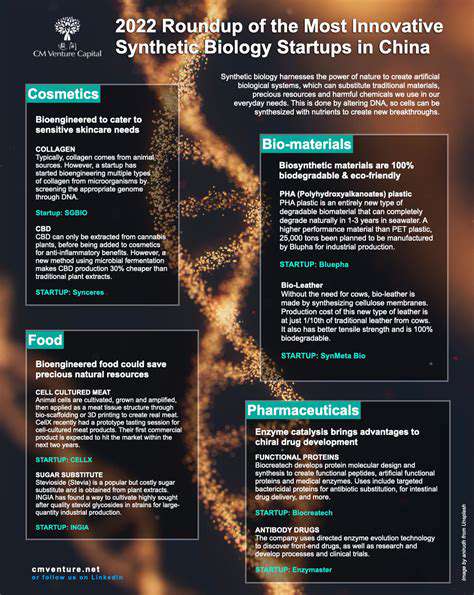

Traditional chemical production relies heavily on fossil fuels, creating significant environmental concerns. Bio-based chemicals, produced through synthetic biology, offer a sustainable alternative. These chemicals can be derived from renewable resources, such as biomass, significantly reducing our dependence on finite resources and minimizing the environmental footprint of chemical manufacturing.

The Role of Synthetic Biology in Bio-Based Chemical Production

Synthetic biology plays a crucial role in optimizing the production of bio-based chemicals. By engineering microorganisms to efficiently produce specific chemicals, scientists can enhance the yield and reduce the cost of these bio-based alternatives. This approach also allows for a more precise control over the chemical structure and properties, leading to improved product quality.

This engineering approach enables the creation of microorganisms that can efficiently convert renewable feedstocks into valuable chemicals, thereby minimizing waste and maximizing resource utilization.

Engineering Microbial Factories for Chemical Synthesis

A key aspect of synthetic biology in bio-based chemical production is the engineering of microbial factories. Scientists meticulously design and construct genetic circuits within microorganisms to direct the production of desired chemicals. This involves identifying and modifying specific genes responsible for metabolic pathways, leading to a more efficient and targeted synthesis of target molecules.

This process often involves the integration of new genetic information into the microbial chassis, allowing for the production of chemicals that are not naturally produced by the organism.

Challenges and Opportunities in Bio-Based Chemical Production

While synthetic biology presents exciting opportunities for bio-based chemical production, several challenges remain. Scalability and cost-effectiveness of bio-manufacturing are crucial considerations. Furthermore, optimizing the metabolic pathways for maximum production yield and developing robust fermentation processes are important research areas.

Despite these challenges, the potential for sustainable and environmentally friendly chemical production through synthetic biology is substantial. The field is rapidly evolving, and significant progress is being made in overcoming these obstacles, paving the way for a more sustainable future.

Future Directions and Applications

Future research in synthetic biology will likely focus on developing more efficient and cost-effective methods for bio-based chemical production. The development of novel microorganisms and tailored metabolic pathways will be key to expanding the range of accessible bio-based chemicals. This could lead to the production of a wider array of materials, from plastics and fuels to pharmaceuticals and agrochemicals.

This innovative approach has the potential to revolutionize various industries and contribute to a more sustainable and environmentally conscious future.

Exploring Diverse Bio-Based Chemical Targets

Harnessing Microbial Metabolism for Novel Chemicals

Microbial organisms, from bacteria to fungi, possess remarkable metabolic capabilities. Synthetic biology offers powerful tools to reprogram these metabolic pathways, enabling the production of a wide array of valuable chemicals. By carefully engineering specific enzymes and pathways, researchers can redirect the metabolic flow to yield desired products, potentially replacing traditional petrochemical processes with more sustainable alternatives. This approach allows for the creation of tailored microbial factories that efficiently convert renewable resources into high-value chemicals, reducing reliance on fossil fuels and minimizing environmental impact.

This process often involves identifying and modifying key enzymes within the microbial chassis. Researchers can also introduce entirely new metabolic pathways, allowing microorganisms to produce chemicals previously inaccessible. This intricate manipulation of metabolic networks holds immense promise for the future of bio-based chemical production.

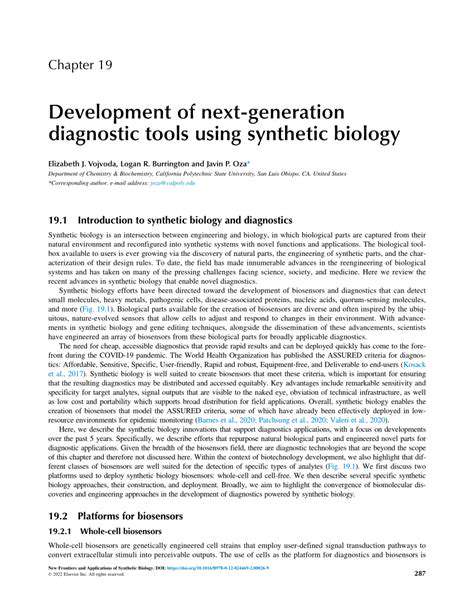

Engineering Enzyme Function for Enhanced Efficiency

Enzymes are the workhorses of metabolic processes. Synthetic biology provides techniques to engineer enzymes for enhanced catalytic activity, stability, and selectivity. By modifying enzyme structures through rational design or directed evolution, researchers can optimize their performance in specific reaction environments, leading to improved product yields and reduced reaction times. This tailored approach to enzyme engineering is crucial for efficient bio-based chemical production.

Further, optimizing enzyme activity in the context of the entire metabolic pathway is essential. Strategies to improve enzyme stability and reduce the need for harsh reaction conditions are critical for scaling up bio-based chemical production.

Utilizing Renewable Feedstocks for Sustainable Production

A key aspect of sustainable bio-based chemical production is the utilization of renewable feedstocks. Synthetic biology can facilitate the efficient conversion of biomass, agricultural residues, and other renewable resources into useful chemicals. This approach not only reduces reliance on finite fossil fuel resources but also reduces the environmental impact associated with traditional chemical production methods. By engineering microorganisms to effectively utilize these feedstocks, we can establish a more circular bioeconomy.

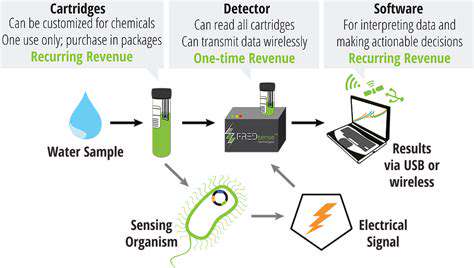

Developing Robust and Scalable Bioprocesses

Moving from laboratory scale to industrial production requires robust and scalable bioprocesses. Synthetic biology plays a vital role in developing these processes by optimizing culture conditions, controlling microbial growth, and enhancing product recovery. Developing efficient downstream processing methods to isolate and purify the desired chemicals is also crucial for industrial viability.

Targeting Specific Chemical Classes for Applications

Synthetic biology can be applied to produce a diverse range of bio-based chemicals across different chemical classes. For example, researchers are exploring the production of bio-based polymers, solvents, and fine chemicals. The ability to customize the production pathways allows for the targeted synthesis of specific chemicals with desired properties for various applications, from materials science to pharmaceuticals.

Different chemical classes present unique challenges and opportunities. Understanding the specific properties and applications of each chemical class enables the development of targeted bio-production strategies.

Addressing Economic and Societal Considerations

The economic viability and societal acceptance of bio-based chemicals are crucial factors in their widespread adoption. Synthetic biology approaches must consider factors like cost-effectiveness, scalability, and the potential environmental and social impacts of the production processes. This includes evaluating the sustainability of feedstock sources and the potential for waste reduction.

Ultimately, the success of bio-based chemical production hinges on creating sustainable solutions that are economically competitive with traditional methods while minimizing environmental harm.

Challenges and Opportunities in Scaling Production

Scaling Production: Initial Hurdles

Scaling up production of synthetic biology-derived products from laboratory settings to industrial-scale facilities presents significant challenges. The initial hurdle often lies in translating the meticulously optimized laboratory protocols to robust, high-throughput processes. This transition frequently requires significant engineering modifications and adaptations to handle larger volumes and maintain consistent product quality. Maintaining the desired biological function and yield under industrial conditions can be a complex undertaking, demanding careful consideration of factors such as temperature, pH, and substrate availability.

Furthermore, the sheer scale of production can introduce new complexities related to resource management and environmental impact. Efficient resource utilization and minimizing waste generation are crucial aspects of scaling up synthetic biology processes sustainably.

Economic Feasibility of Large-Scale Production

One of the major obstacles in scaling synthetic biology production is ensuring the economic viability of the process. The cost of raw materials, energy, and labor must be carefully evaluated and optimized to achieve a competitive price point for the final product. Developing cost-effective production strategies, including efficient bioreactor designs and optimized fermentation conditions, is paramount for commercial success.

The potential for economies of scale is crucial to consider. Larger production volumes can potentially lower production costs per unit, making the product more attractive to the market. However, the initial investment required for setting up large-scale facilities can be substantial, demanding careful financial planning and market analysis to ensure profitability.

Maintaining Product Quality and Consistency

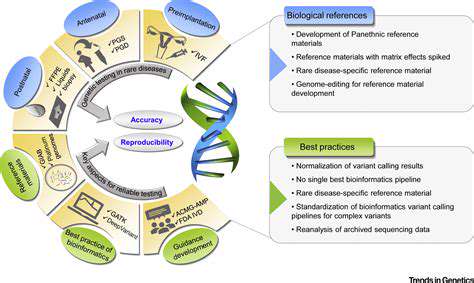

Maintaining consistent product quality and yield across large-scale production runs is essential for consumer trust and market acceptance. The biological processes involved in synthetic biology can be susceptible to variations in environmental factors, potentially leading to fluctuations in product quality. Implementing robust quality control measures throughout the production process is crucial to ensure product consistency and safety.

Standardization of protocols and process parameters is vital for maintaining quality. Continuous monitoring and control systems are necessary to identify and mitigate potential deviations from the desired production profile. This requires sophisticated sensor technology and real-time data analysis capabilities.

Engineering Challenges in Bioreactor Design

Designing bioreactors capable of handling large volumes and maintaining optimal conditions for microbial growth and product synthesis is a significant engineering challenge. The complex interplay of factors such as mixing, oxygen transfer, and temperature control within the bioreactor needs careful consideration. The size, shape, and material of the bioreactor must be optimized for efficient mass transfer and product recovery.

Regulatory and Safety Considerations

The production of novel biological products through synthetic biology necessitates careful consideration of regulatory and safety guidelines. Ensuring the safety and efficacy of the final product, minimizing potential environmental impacts, and complying with regulatory frameworks are critical steps in bringing these products to market. Stringent safety protocols must be in place to prevent unintended consequences and minimize potential risks.

Supply Chain Optimization and Resource Management

Establishing a robust and efficient supply chain for raw materials and supporting infrastructure is crucial for large-scale production. Securing reliable and cost-effective sources for essential nutrients, reagents, and energy inputs is important. Optimizing resource utilization throughout the production process, from initial feedstock sourcing to waste management, is paramount. Sustainable practices and resource efficiency are vital to long-term viability.

Market Acceptance and Consumer Perception

The successful scaling of synthetic biology production hinges on successfully navigating market acceptance and consumer perception. Transparency and clear communication about the origins and benefits of bio-based products are essential. Addressing potential concerns about safety, environmental impact, and ethical implications is critical for building public trust and driving market adoption. Effective marketing strategies that highlight the sustainability and value proposition of bio-based products are key.