Metabolic Engineering for Enhanced Product Formation

Metabolic Engineering Strategies

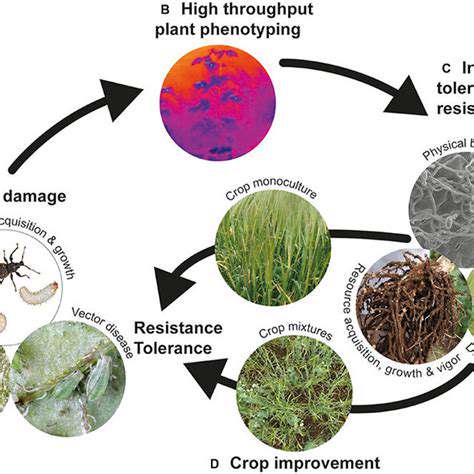

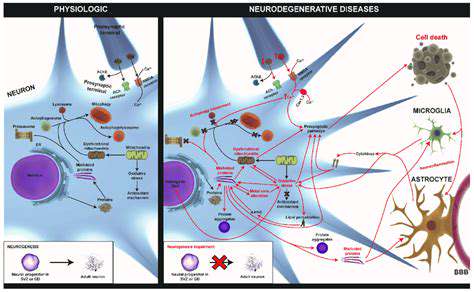

Metabolic engineering, a powerful tool in biotechnology, involves manipulating cellular metabolic pathways to achieve desired outcomes. This intricate process often involves modifying existing enzymes, introducing new ones, or altering the regulation of existing pathways. By carefully controlling these processes, engineers can significantly influence the production of valuable metabolites, such as pharmaceuticals, biofuels, or industrial chemicals. This targeted approach holds immense potential for improving efficiency and yield in various applications.

A key aspect of metabolic engineering involves a deep understanding of the organism's existing metabolic network. This includes identifying bottlenecks in the pathway and understanding the regulatory mechanisms that govern the flow of metabolites through the system. This knowledge is crucial for designing effective strategies to enhance production of target molecules.

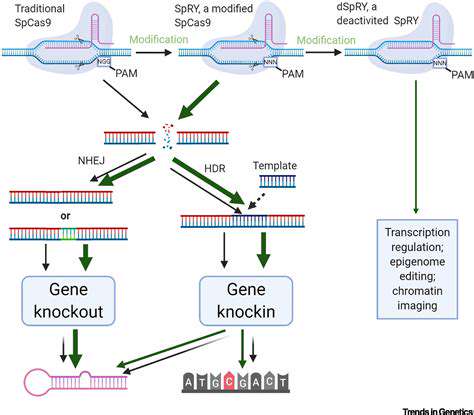

Genetic Tools for Pathway Modification

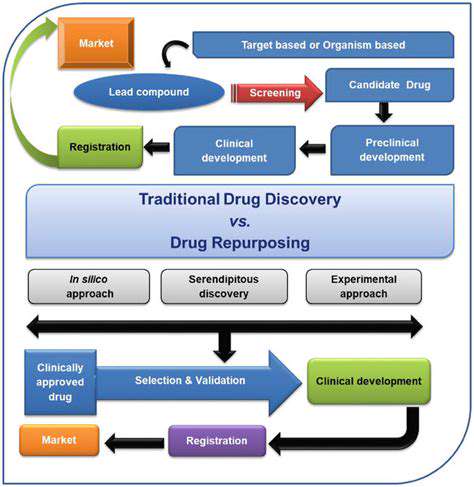

Various genetic tools are employed in metabolic engineering to achieve specific modifications. These tools include gene knockout, overexpression, and gene replacement strategies. Gene knockouts are used to eliminate undesirable pathways or enzymes, while overexpression of genes can enhance the production of desired metabolites. Gene replacement allows for the introduction of novel enzymes or pathways into the organism.

The choice of genetic tools depends on the specific metabolic pathway being targeted and the desired outcome. Careful consideration of the potential consequences of each method is crucial to ensure successful and predictable results. The selection of appropriate vectors and promoters is also essential for efficient gene delivery and expression.

Optimizing Metabolic Flux

Metabolic flux analysis is a critical technique in metabolic engineering. It allows researchers to quantify the flow of metabolites through various pathways within a cell. By analyzing this data, engineers can identify bottlenecks and optimize the overall metabolic flux to enhance the production of desired products. Understanding the constraints and limitations within the metabolic network is essential for developing effective strategies to maximize the desired product.

Computational modeling is often employed in conjunction with flux analysis to predict the effects of genetic modifications on metabolic flux. This approach allows for virtual testing of different strategies before implementing them in real organisms, saving time and resources.

Strain Development for Enhanced Production

Metabolic engineering often involves creating new strains of microorganisms with enhanced production capabilities. This can involve combining several genetic modifications to achieve a synergistic effect. Optimizing the production of a desired product frequently requires a combination of several modifications to the organism's metabolic machinery. The creation of such strains necessitates careful consideration of genetic stability, scalability, and potential off-target effects.

Furthermore, the use of combinatorial approaches, where multiple genetic changes are introduced simultaneously, can significantly enhance the overall production yield. This strategy often leads to more dramatic improvements than individual modifications.

Applications and Challenges in Metabolic Engineering

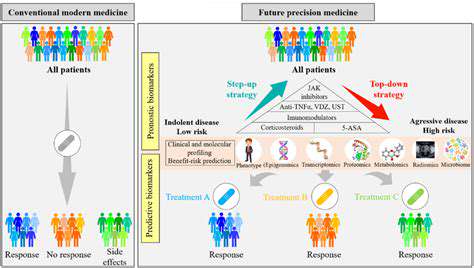

Metabolic engineering has a wide range of applications, including the production of biofuels, pharmaceuticals, and industrial chemicals. It plays a crucial role in developing sustainable alternatives to traditional manufacturing processes. This approach holds significant promise for addressing global challenges related to energy and resource sustainability.

However, challenges remain in metabolic engineering, such as the complexity of metabolic networks and the potential for unintended consequences of genetic modifications. Further research and development are necessary to overcome these hurdles and fully realize the potential of this powerful technology.

Process Intensification and Scale-up Strategies

Process Intensification Strategies

Process intensification is a crucial area of research and development in chemical engineering, focusing on designing and implementing processes that are more efficient, safer, and environmentally friendly. This involves combining multiple unit operations into a single, integrated system, leading to reduced footprint and energy consumption. For instance, integrating reaction, separation, and mixing steps within a single reactor can significantly improve overall process efficiency and productivity.

Several strategies are employed to achieve process intensification. These include microreactor technology, which utilizes small-scale reactors to enhance mass and heat transfer; membrane separation techniques, enabling efficient separation of components; and the use of advanced catalytic materials, which lead to faster reaction rates and reduced energy requirements. By applying these strategic approaches, process intensification seeks to improve the performance and reduce the environmental impact of chemical manufacturing processes.

Scale-up Considerations

Scaling up process intensification strategies is a critical challenge. The behavior of a process at a laboratory or pilot scale may not always translate directly to a larger industrial scale. Factors such as mixing characteristics, heat and mass transfer rates, and reactor hydrodynamics can change significantly with increasing scale, potentially impacting the performance and safety of the intensified process. Careful consideration must be given to the specific requirements of the larger-scale operation to ensure successful implementation.

Thorough process modeling and simulation, along with rigorous experimental validation at different scales, are indispensable tools for successful scale-up. This allows engineers to identify potential issues and refine the design to ensure optimal performance and safety at larger production capacities. Furthermore, the use of advanced process control systems and monitoring equipment is crucial for maintaining process stability and efficiency during scale-up.

Economic and Environmental Benefits

Process intensification offers significant economic and environmental benefits. Reduced capital investment and operating costs are often achievable due to the smaller footprint and higher efficiency of intensified processes. This translates to lower manufacturing costs and increased profitability for industrial companies. Furthermore, process intensification often leads to a smaller environmental impact by reducing energy consumption, waste generation, and emissions. The use of less hazardous chemicals and the reduction of hazardous waste streams further contribute to the positive environmental footprint of such processes.

These advantages make process intensification a key driver for innovation in the chemical and related industries. Sustainable development goals are increasingly emphasizing the need for efficient and environmentally responsible processes, making process intensification a vital component of future manufacturing strategies.