Introduction to Biotechnology in Industrial Chemistry

Fundamentals of Biotechnology

Biotechnology, a field encompassing diverse applications of biological systems and organisms, is rapidly transforming various industries. From pharmaceuticals to agriculture, biotechnology offers innovative solutions to pressing global challenges. Understanding the fundamental principles underpinning this field is crucial for appreciating its potential and impact. This includes comprehending the intricate interactions between living organisms and their environment, as well as harnessing these interactions for practical purposes. Biotechnology relies heavily on scientific principles, particularly in areas like genetics, microbiology, and biochemistry.

The historical roots of biotechnology lie in ancient practices like fermentation and selective breeding. These rudimentary techniques laid the groundwork for modern advancements. Over time, our understanding of biological processes has grown exponentially, leading to groundbreaking discoveries and technological innovations. This evolution has been particularly significant in the past century, marked by major breakthroughs in genetic engineering and molecular biology. This advanced knowledge now enables us to manipulate biological systems with unprecedented precision.

Applications in Various Industries

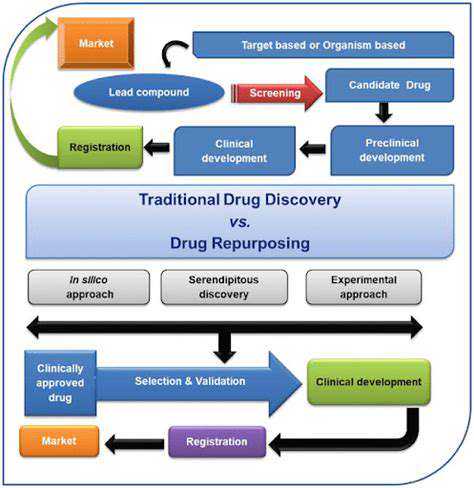

Biotechnology's influence extends across numerous industries, revolutionizing processes and products. In the pharmaceutical sector, biotechnology is crucial for developing life-saving medications, including vaccines and therapies targeting specific diseases. This involves manipulating microorganisms and cells to produce valuable compounds and proteins.

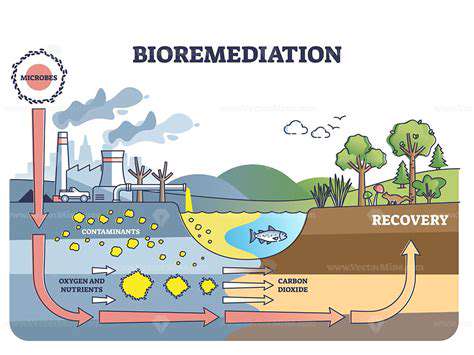

Agricultural applications of biotechnology are also significant, enhancing crop yields and nutritional value. Genetically modified organisms (GMOs) are a prime example of this application. These advancements help address food security concerns and improve agricultural sustainability. Further, biotechnology is increasingly used in environmental remediation, playing a key role in bioremediation and waste management.

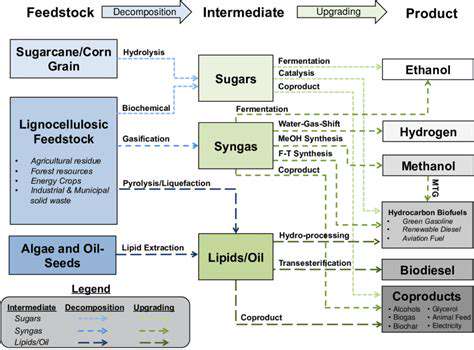

Biotechnology's role in industrial processes is also notable, enhancing efficiency and reducing environmental impact. This includes applications in biofuel production, bioprocessing, and industrial enzyme production. These innovative approaches are poised to transform how we conduct various industrial activities.

Ethical Considerations and Future Trends

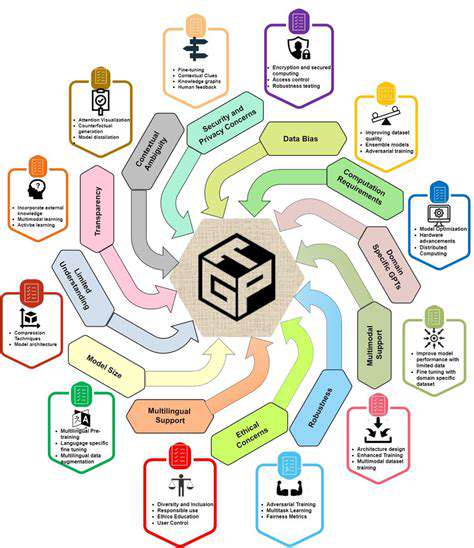

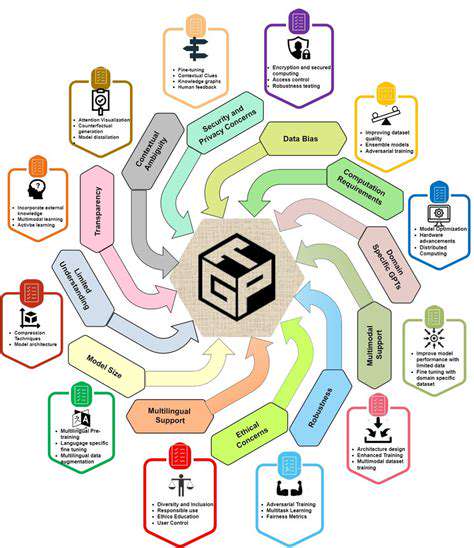

As biotechnology continues its rapid advancement, careful consideration of ethical implications is essential. Issues surrounding genetic modification, intellectual property rights, and the potential for misuse of these powerful tools must be addressed proactively. Open dialogue and robust ethical frameworks are crucial to ensure responsible development and application of biotechnology. Public engagement and transparency are essential to build trust and address concerns effectively.

Looking ahead, the future of biotechnology is promising. Continued research and development are expected to unlock further advancements in diagnostics, therapeutics, and sustainable practices. We can anticipate even more sophisticated applications of biotechnology in areas like personalized medicine, regenerative medicine, and synthetic biology. These advancements hold the potential to dramatically improve human health and address global challenges.

Microbial Fermentation for Chemical Synthesis

Microbial Diversity in Fermentation

A diverse range of microorganisms, including bacteria, fungi, and yeasts, possess unique metabolic capabilities that can be harnessed for chemical synthesis. Different species exhibit varying enzyme repertoires and substrate preferences, enabling the production of a wide array of chemicals. Understanding these microbial variations and their potential for specific chemical transformations is crucial for optimizing fermentation processes.

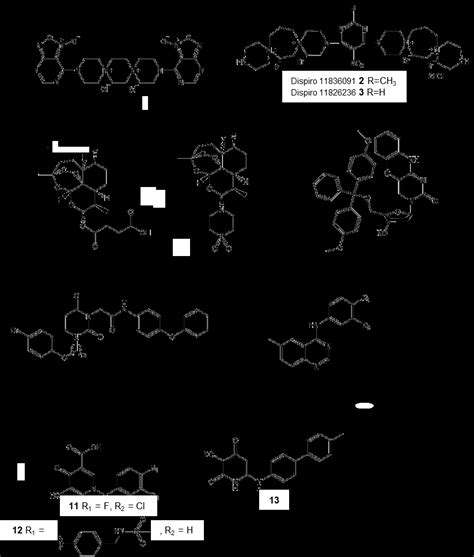

Selecting the appropriate microbial strain is paramount. Researchers meticulously screen and engineer microorganisms to enhance their productivity and efficiency in synthesizing target chemicals. Genetic modifications, metabolic engineering, and other innovative techniques allow tailored microbial production platforms to be developed, ultimately boosting the yield and reducing production costs.

Fermentation Process Optimization

Optimizing fermentation conditions is essential for maximizing chemical yield and minimizing production costs. Factors such as temperature, pH, aeration, and nutrient supply directly impact microbial growth and metabolic activity. Precise control over these parameters through careful monitoring and adjustment is critical for achieving optimal performance.

Furthermore, understanding the kinetics of the fermentation process, including the growth rate of microorganisms and the rate of chemical production, allows for the development of strategies to enhance efficiency. Mathematical modeling and simulations can play a key role in optimizing fermentation strategies and predicting outcomes.

Bioreactor Design and Engineering

The design and engineering of bioreactors are vital for efficient microbial fermentation. Different bioreactor types, such as stirred-tank bioreactors and airlift bioreactors, offer varying degrees of control and mixing capabilities. Choosing the appropriate bioreactor type and optimizing its design parameters is essential for ensuring efficient mass transfer, heat transfer, and mixing within the fermentation system.

Scalability is a significant aspect of bioreactor design. The ability to scale up fermentation processes from laboratory-scale to industrial production is crucial for commercial viability. Bioreactor designs must be adaptable to accommodate larger volumes and maintain high-quality product yields at an industrial scale.

Metabolic Engineering for Enhanced Production

Metabolic engineering plays a pivotal role in enhancing the production of specific chemicals through microbial fermentation. This approach involves manipulating the metabolic pathways of microorganisms to direct their metabolic efforts towards the desired chemical product. Strategies such as overexpressing key enzymes, deleting nonessential pathways, and introducing novel metabolic pathways can significantly increase the yield of target chemicals.

Downstream Processing and Product Recovery

The downstream processing of the fermented broth is a critical step in the overall production process. Effective separation and purification methods are needed to isolate the desired chemical product from the microbial biomass and other byproducts. Different separation techniques, such as filtration, extraction, and chromatography, are employed depending on the nature of the desired product and the characteristics of the fermentation broth.

The efficiency of downstream processing directly impacts the overall cost-effectiveness of the production process. Developing cost-effective and environmentally friendly methods for product recovery is crucial for ensuring the commercial viability of microbial fermentation for chemical synthesis.

Challenges and Future Directions

Scalable Production of Bio-based Chemicals

One of the major hurdles in the application of biotechnology to industrial chemical production is the scalability of the process. Current methods often struggle to produce chemicals at the volumes required by industry. Researchers are actively exploring novel bioreactor designs, optimized fermentation strategies, and genetic engineering techniques to enhance the productivity of microbial cell factories. This involves not only maximizing the output of the desired chemical but also minimizing the production of unwanted byproducts and ensuring efficient downstream processing.

Developing cost-effective and sustainable large-scale bioreactors capable of handling high cell densities and maintaining optimal conditions for biotransformation is a critical area of focus. Innovative approaches such as integrating bioprocessing with existing industrial infrastructure are being investigated to streamline the transition from laboratory to industrial settings, ultimately lowering the overall cost of production.

Cost-Effectiveness and Economic Viability

The economic feasibility of bio-based chemical production is a significant consideration. Biotechnology often incurs higher initial capital costs for equipment and infrastructure compared to conventional chemical processes. However, the long-term cost advantages of using renewable feedstocks and avoiding fossil fuel dependence need to be carefully evaluated.

Exploring strategies to reduce production costs, such as optimizing feedstock utilization, enhancing microbial strain performance, and minimizing energy consumption during bioprocessing, is crucial for making bio-based chemicals competitive with their petrochemical counterparts. Life cycle assessments and thorough economic modeling are essential to accurately assess the overall economic viability of these processes.

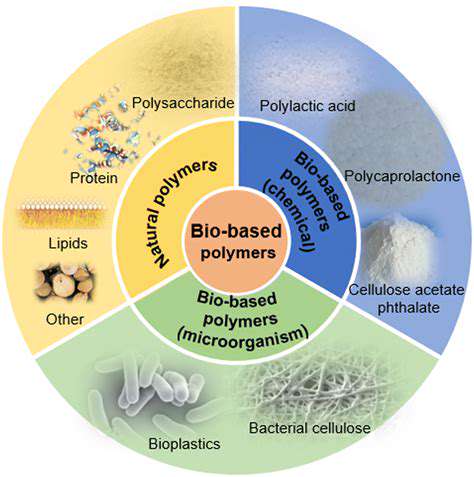

Feedstock Sustainability and Availability

The sustainability of the feedstock used in bio-based chemical production is paramount. Using agricultural residues, industrial waste streams, or non-food biomass sources can significantly reduce the environmental impact of the overall process. However, the availability and consistency of these feedstocks need to be carefully assessed to ensure reliable supply chains and avoid potential competition with food production.

Strain Improvement and Metabolic Engineering

Improving the performance of microbial strains is essential for enhancing the yield and selectivity of desired chemicals. Metabolic engineering techniques, such as modifying existing pathways, introducing new pathways, and optimizing enzyme activity, are key tools for achieving this goal. These techniques involve careful manipulation of the genetic material of microorganisms to enhance their ability to produce the desired chemical with high efficiency.

Downstream Processing Challenges

Efficient downstream processing of bio-based chemicals is often a bottleneck in the overall production process. This step involves separating the desired product from the fermentation broth, purifying it to meet the required specifications, and preparing it for market application. Developing cost-effective and environmentally friendly downstream processing technologies is critical for reducing the overall production cost and environmental footprint.

Regulatory Framework and Policy Support

The development and implementation of appropriate regulatory frameworks are essential for encouraging the adoption of bio-based chemical technologies. Clear guidelines and policies that address safety concerns, environmental impacts, and market access are crucial for fostering innovation and investment in this field. Government incentives and support for research and development activities can also play a significant role in accelerating the transition to bio-based industrial chemicals.

Environmental Impact Assessment and Sustainability

A comprehensive environmental impact assessment is crucial to evaluate the overall sustainability of bio-based chemical production processes. This assessment should consider the entire life cycle, from feedstock sourcing and cultivation to downstream processing and end-of-life management. Minimizing environmental impacts, such as greenhouse gas emissions, water consumption, and waste generation, is vital for the long-term success and acceptance of bio-based technologies in the industrial sector. Sustainable practices throughout the production chain are essential for creating a truly environmentally responsible alternative to petroleum-based chemicals.