Bioreactor Design and Applications in Bioremediation

Bioreactor Types and their Characteristics

Bioreactors come in various shapes and sizes, each tailored for specific microbial or cellular processes. Stirred-tank bioreactors, for example, are widely used for their efficient mixing capabilities, promoting homogenous distribution of nutrients and oxygen throughout the vessel. They are often chosen for applications where high cell densities or fast reaction rates are crucial, like in large-scale fermentation processes. Other types include airlift bioreactors, which rely on gas bubbles for mixing, and packed-bed bioreactors, where cells or enzymes are immobilized on a solid support.

Understanding the specific requirements of each process is key to selecting the appropriate bioreactor type. Factors like the desired cell density, the nature of the reaction, and the scale of production will all influence the choice.

Key Design Considerations for Bioreactors

A crucial aspect of bioreactor design is ensuring optimal conditions for microbial growth and product formation. This involves meticulous consideration of factors like temperature, pH, and dissolved oxygen (DO) levels. Maintaining these parameters within the optimal ranges is paramount to achieving high yields and productivity.

Furthermore, the bioreactor's physical structure, including the material of construction and the presence of baffles or impellers, significantly impacts mixing efficiency and heat transfer. Proper design minimizes shear stress, protecting delicate cells from damage, while maximizing mass transfer and heat exchange.

Material Selection and its Importance

The choice of material for bioreactor construction is critical. Materials must be chemically inert, resistant to corrosion by the process fluids, and compatible with the microorganisms or cells being cultured. Stainless steel, for instance, is a common choice due to its resistance to many chemicals and its ability to withstand sterilization procedures.

Selecting the right material directly affects the safety and longevity of the bioreactor. The material must also withstand the pressures and temperatures encountered during operation to prevent leakage or failure.

Mixing and Mass Transfer in Bioreactors

Effective mixing in a bioreactor ensures uniform distribution of nutrients, oxygen, and other essential components throughout the culture medium. This uniform distribution promotes optimal growth conditions for microorganisms and maximizes the reaction rate. Proper mixing is essential for consistent product formation and minimizing variability in the process.

Mass transfer, the movement of substances between phases (e.g., gas and liquid), is also a critical aspect of bioreactor design. Efficient mass transfer is crucial for supplying oxygen to the cells and removing byproducts.

Sterilization and Contamination Control

Sterilization procedures are essential to prevent contamination of the bioreactor and its contents. Effective sterilization methods are critical to ensuring consistent and high-quality results in bioreactor operations. This often involves steam sterilization, filtration, or chemical treatments. Thorough cleaning and sanitization procedures are equally important to maintain sterility between batches.

Maintaining a sterile environment is paramount in preventing unwanted organisms from proliferating, which can drastically reduce yields and product quality.

Scalability and Cost-Effectiveness

Scaling up bioreactor designs from laboratory to industrial scale is a critical consideration. The design must accommodate larger volumes while maintaining similar performance parameters. Efficient scalability is crucial for translating research discoveries into commercial applications.

Cost-effective bioreactor design is also vital. The materials, construction, and operational costs should be considered to ensure the economic viability of the process.

Applications of Bioreactors in Various Industries

Bioreactors find applications in various industries, including pharmaceuticals, food and beverages, and biofuels production. In pharmaceuticals, they are used for producing valuable proteins and therapeutic agents. In the food and beverage industry, bioreactors are employed in the production of fermented foods. Bioreactor technology is revolutionizing the biofuel industry by offering efficient ways to produce biofuels from biomass.

The versatility of bioreactor designs makes them applicable to a broad range of industrial processes.

The Future of Biotechnology in Bioremediation

The Convergence of Biotechnology and Biomaterials

Biotechnology is rapidly evolving, and its intersection with biomaterials is poised to revolutionize various industries. This convergence promises innovative solutions in areas like tissue engineering, drug delivery systems, and bio-inspired materials science. Biomaterials, derived from natural sources or synthetically designed, can be engineered to interact precisely with biological systems, leading to a new era of personalized medicine and advanced therapies. Scientists are exploring the potential of biomaterials to create scaffolds for tissue regeneration, promoting faster healing and minimizing the need for traditional surgical interventions.

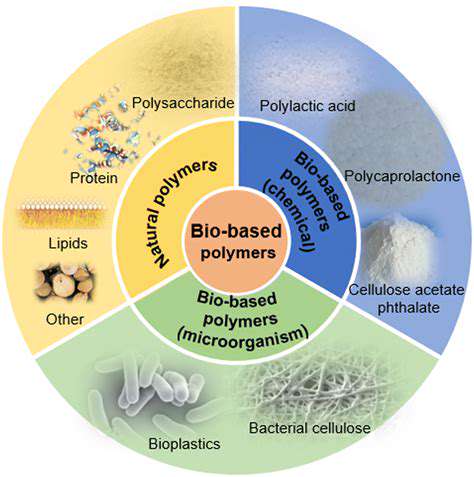

The development of biocompatible and biodegradable polymers, ceramics, and composites is crucial for creating materials that can seamlessly integrate with the human body. This integration is essential for the success of many biotechnological applications. Furthermore, the ability to precisely control the properties of these materials, such as their mechanical strength, biodegradability, and surface chemistry, is a key aspect of this exciting field.

Personalized Medicine and Diagnostics

Biotechnology is driving the development of personalized medicine, tailoring treatments to individual genetic profiles and disease characteristics. This approach holds immense promise for improving treatment efficacy and reducing adverse effects. This shift will also lead to more accurate diagnostics, enabling earlier detection of diseases and enabling preventative measures.

Advanced diagnostic tools, often based on biotechnology principles, are becoming increasingly sophisticated, allowing for more precise identification of diseases at their earliest stages. This early detection can have a profound impact on patient outcomes and public health initiatives. The potential for personalized medicine to enhance the quality of life for countless individuals is undeniable.

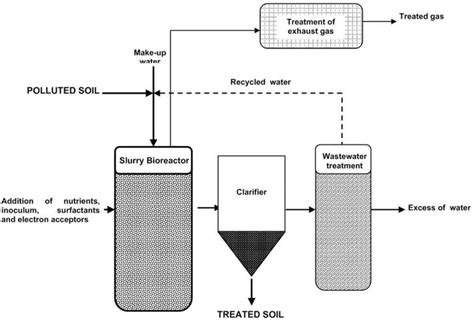

Bioremediation and Environmental Biotechnology

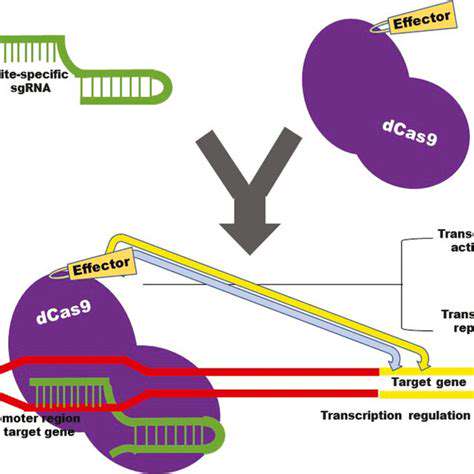

Biotechnology offers innovative solutions for environmental challenges, such as pollution cleanup and waste management. Microbial organisms, engineered for specific tasks, can be employed to break down pollutants and restore contaminated environments. This approach is significantly more sustainable than traditional chemical methods and offers a promising avenue for addressing environmental crises.

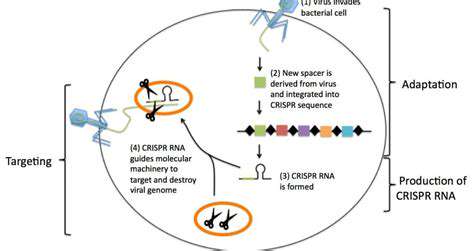

The use of genetically modified microorganisms for bioremediation is a rapidly growing field. These organisms can be designed to degrade specific pollutants, making them valuable tools in the fight against environmental degradation. This approach is vital for the restoration of ecosystems and the preservation of biodiversity.

Agricultural Biotechnology and Food Security

Biotechnology plays a vital role in enhancing agricultural productivity and ensuring global food security. Techniques such as genetic modification can improve crop yields, enhance nutritional value, and make crops more resistant to pests and environmental stresses. This is an important step in ensuring the world's growing population has access to sufficient and nutritious food.

Genetically modified crops can contribute to higher yields, potentially reducing the need for land expansion and minimizing environmental impact. This is crucial for sustainable agriculture and combating food shortages. Additionally, biofertilizers and biopesticides, derived from biological processes, can further support sustainable agricultural practices.

Biomanufacturing and Industrial Applications

Biotechnology is transforming industrial processes, leading to the development of sustainable and efficient production methods. Biomanufacturing relies on biological systems for the creation of valuable products, from pharmaceuticals to biofuels. The use of enzymes and microorganisms to synthesize various products is gaining significant traction.

This approach to manufacturing offers significant advantages over traditional chemical methods, often leading to reduced environmental impact and more sustainable processes. Furthermore, the potential for tailoring biological systems to specific industrial needs opens doors to the creation of novel materials and products.

Ethical Considerations and Regulatory Frameworks

The rapid advancements in biotechnology raise significant ethical considerations, particularly concerning the potential risks and benefits associated with genetic engineering and gene editing. The development of robust regulatory frameworks is crucial to ensure the responsible and ethical application of these technologies. Careful consideration must be given to the implications of such technologies, both on a societal and individual level.

Balancing scientific innovation with ethical considerations is paramount in the development and implementation of biotechnology. Transparent public discourse, robust regulatory oversight, and ongoing societal dialogue are essential for navigating the complex ethical landscape of this rapidly evolving field.