Biofuels: Harnessing Nature's Power

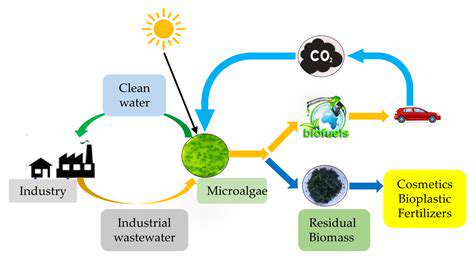

Biofuels represent a promising avenue for transitioning away from fossil fuels, offering a potentially sustainable alternative energy source. Derived from biomass, these fuels can be produced from various feedstocks, including agricultural crops, forestry residues, and algae. This diverse range of feedstocks allows for a degree of flexibility in biofuel production, potentially adapting to local resources and reducing reliance on specific, often geographically concentrated, fossil fuel supplies.

The Environmental Impact of Biofuels

While biofuels are touted as a sustainable alternative, their environmental impact is a complex issue. The production of biofuels can have both positive and negative effects on ecosystems, depending on the specific feedstock and the methods employed. Sustainable practices, such as using waste materials or non-food crops, and minimizing land-use changes, are crucial to maximizing the environmental benefits and mitigating potential negative impacts.

Biofuel Production Methods: A Diverse Landscape

Various methods exist for producing biofuels, each with its own set of advantages and disadvantages. These range from traditional methods like ethanol production from corn to more advanced techniques such as biodiesel production from algae. The choice of method often depends on factors like available resources, technological advancements, and economic feasibility. Understanding the nuances of each production method is vital for assessing their long-term viability.

Economic Viability and Market Trends

The economic viability of biofuels is a key factor in their widespread adoption. The fluctuating costs of feedstocks, production processes, and competing energy sources significantly impact the market competitiveness of biofuels. Government policies and incentives play a crucial role in shaping the economic landscape for biofuels and fostering investment. Market trends and consumer demand also influence the future direction of the biofuel industry.

Challenges and Opportunities in Scaling Up Biofuel Production

Scaling up biofuel production to meet global energy needs presents significant challenges, including the potential for competition with food production, the need for efficient and sustainable production processes, and the development of infrastructure for distribution and use. Overcoming these challenges is crucial to realizing the full potential of biofuels as a sustainable energy source. However, there are also opportunities to develop innovative solutions for sustainable biofuel production, such as utilizing non-food crops and waste materials.

The Future of Biofuels: A Sustainable Energy Solution?

The future of biofuels remains uncertain, but their potential as a sustainable energy source is undeniable. Technological advancements and innovative approaches are constantly being explored to overcome the challenges and maximize the benefits of biofuel production. Further research and development, combined with supportive policies and investments, are essential to unlock the full potential of biofuels and contribute to a cleaner, more sustainable energy future for the planet. The long-term success of biofuels hinges on our ability to balance environmental concerns with economic viability.

Enzyme-Based Technologies for Biofuel Production

Improving Enzyme Efficiency for Enhanced Biofuel Production

Enzymes play a critical role in biofuel production, catalyzing the conversion of biomass into biofuels. Improving the efficiency of these enzymes is a key area of research. This involves optimizing enzyme activity at various temperatures and pH levels, as well as developing strategies for stabilizing enzymes under harsh reaction conditions. Such improvements can lead to higher yields of biofuels and reduced production costs, making biofuel production more economically viable.

One promising approach is the use of enzyme cocktails, which can enhance the overall efficiency of the biofuel production process. By combining different enzymes with complementary activities, the conversion of complex biomass into simpler biofuel precursors can be more comprehensive and streamlined.

Exploring Novel Enzyme Sources for Biofuel Production

Identifying and characterizing novel enzymes from diverse microbial sources is crucial for developing more efficient and cost-effective biofuel production strategies. Extremophiles, microorganisms thriving in extreme environments, often possess enzymes with unique properties, including optimal activity at high temperatures or in acidic/alkaline conditions. These enzymes could be adapted for use in industrial biofuel production, potentially leading to significant advancements in the field.

The exploration of new enzyme sources will lead to enzymes with improved stability, activity, and specificity, all of which are key factors in optimizing biofuel production.

Enzyme Immobilization for Enhanced Biofuel Production

Immobilizing enzymes onto solid supports can significantly enhance their stability and reusability in biofuel production processes. This approach protects enzymes from denaturation and allows for facile separation of the enzymes from the reaction mixture, making the process more efficient and economical. Different immobilization techniques, such as entrapment and covalent binding, offer various advantages and disadvantages, and the optimal choice will depend on the specific enzyme and biofuel production process.

Furthermore, immobilization can lead to improved enzyme activity and reduced contamination risks. The reduced risk of contamination is an important factor in maintaining the quality and purity of the biofuel product.

Metabolic Engineering for Enhanced Enzyme Production

Metabolic engineering strategies can be employed to increase the production of enzymes within the microbial cell, thereby boosting the overall biofuel production efficiency. Modifying the genetic makeup of the organism responsible for producing the enzymes can lead to higher enzyme yields. This approach involves manipulating the expression levels of enzyme-coding genes through various genetic techniques, ultimately increasing the rate of biofuel production.

Optimizing Reaction Conditions for Enzyme-Catalyzed Biofuel Production

Optimizing reaction conditions, such as temperature, pH, and substrate concentration, is essential for maximizing enzyme activity and biofuel yield. Precise control of these parameters can significantly impact the overall efficiency of the biofuel production process. Finding the optimal conditions often involves extensive experimentation and can vary considerably depending on the enzyme and substrate.

Cost-Effective Enzyme Production and Purification Strategies

Developing cost-effective strategies for enzyme production and purification is essential for making biofuel production economically viable. Utilizing readily available and inexpensive substrates for enzyme production, along with efficient purification methods, will reduce the overall production costs. Bioreactor design plays a crucial role in this regard, as optimizing the bioreactor design for enzyme production can lead to significant cost savings.

Enzyme Characterization and Screening for Biofuel Production

Thorough characterization of enzymes involved in biofuel production is essential for understanding their properties, including their activity, stability, and specificity. This characterization provides insights into the mechanisms of biofuel production and allows for the development of tailored enzyme-based processes. Screening for enzymes with improved properties for biofuel production can lead to significant improvements in the overall process.