Bio-Based Composites for Sustainable Applications

Bio-Based Composites: An Introduction

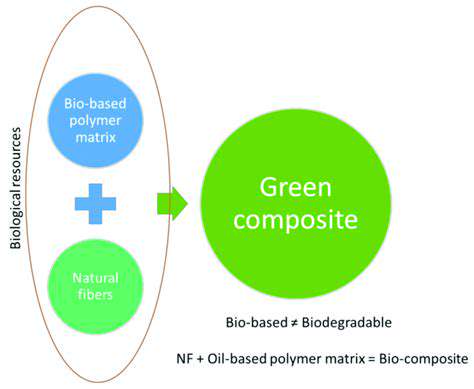

Imagine materials that grow in fields rather than being pumped from oil wells. Bio-based composites represent this paradigm shift, utilizing renewable biological resources as their foundation. Unlike conventional composites dependent on petrochemicals, these sustainable alternatives address pressing environmental concerns. They embody the transition from linear take-make-waste models to regenerative material cycles. Their ability to decompose naturally offers solutions to persistent waste problems.

Industries from automotive to consumer goods are adopting these materials, though not without challenges. The secret lies in artfully combining natural polymers with other eco-friendly components to achieve performance rivaling traditional materials. This balancing act between sustainability and functionality defines the field's cutting edge.

Key Components of Bio-Based Composites

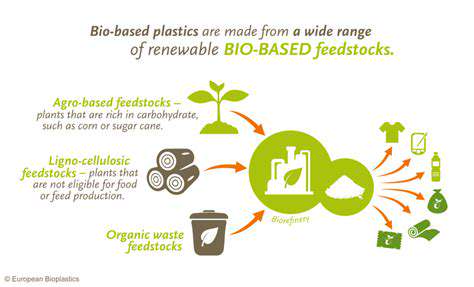

Nature's polymer library—cellulose, lignin, starch, and proteins—forms the backbone of these materials. Cellulose provides rigidity like wood's cellular structure, while starch offers pliability similar to plant roots. Material scientists carefully select these components much like chefs combine ingredients, each contributing distinct properties to the final recipe.

Reinforcements often include agricultural byproducts—hemp fibers strengthen like steel rebars in concrete, while rice husk ash adds durability. The magic happens in the synergy between these elements, creating composites where the whole exceeds the sum of parts.

Advantages of Bio-Based Composites

The environmental calculus favors these materials decisively. For every ton of petroleum-based plastic replaced, approximately 2-3 tons of CO₂ emissions are avoided. This carbon math makes them crucial players in climate change mitigation strategies.

End-of-life scenarios reveal another advantage: where conventional plastics persist for centuries, many bio-composites decompose within months under proper conditions. This characteristic proves particularly valuable for single-use items dominating modern consumption patterns.

Challenges in Bio-Based Composite Development

Performance parity remains an uphill battle. While some natural fibers match glass fibers in strength-to-weight ratios, consistency issues plague large-scale production. Variability in natural materials—unlike the uniformity of synthetic polymers—poses persistent quality control challenges.

Economic realities also intrude. Though prices fluctuate, petroleum derivatives often undercut bio-alternatives. However, as carbon pricing mechanisms evolve and production scales up, this gap continues narrowing meaningfully.

Applications of Bio-Based Composites

Automakers now incorporate these materials in door panels and trim components, reducing vehicle weight by 10-15%. Construction sees potential in biodegradable insulation and sustainable concrete alternatives. The packaging industry particularly benefits, where compostable food containers address both functionality and waste concerns.

Emerging applications surprise even experts—some marine vessels now use flax-reinforced hulls that resist saltwater corrosion better than fiberglass. Aerospace experiments with fungal mycelium composites for lightweight interior components demonstrate the field's innovative spirit.

Future Trends in Bio-Based Composites

Next-generation research explores molecular-level engineering of plant-based polymers. Scientists manipulate cellulose nanocrystals to create transparent films stronger than steel. The coming decade will likely witness bio-composites surpassing petroleum-based materials in specific high-performance applications.

Manufacturing innovations like 3D printing with algae-based resins and self-assembling bacterial cellulose point toward radically different production paradigms. These developments could decentralize material production, bringing it closer to end-users.

Sustainability and the Circular Economy

These materials represent more than technical solutions—they embody an economic philosophy. When a car part can decompose into fertilizer or a building material can be replanted as crops, we redefine value chains. This represents nothing less than a Copernican revolution in material science.

The ultimate goal? Industrial ecosystems where waste becomes feedstock, and products designed from inception for graceful degradation. As regulatory pressures mount and consumer preferences shift, bio-composites position themselves as linchpins of this transformation.