Designing Biological Factories for Material Production

Harnessing Cellular Machinery for Synthesis

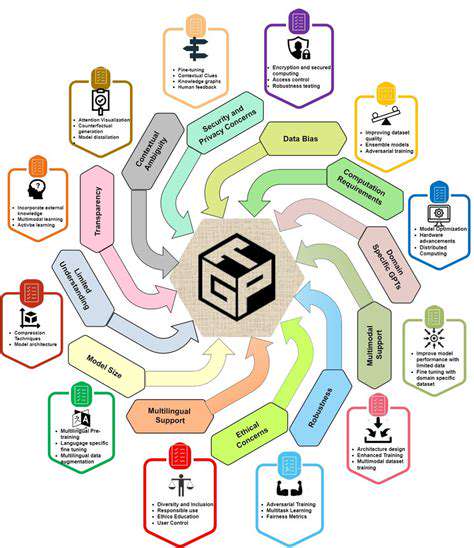

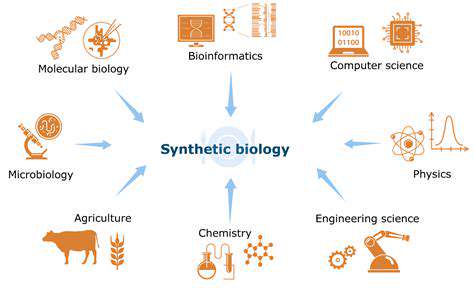

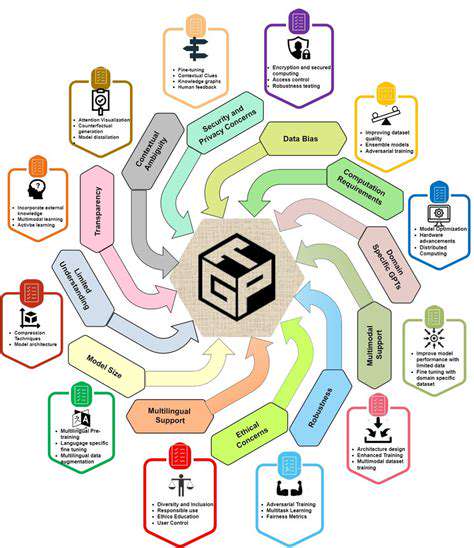

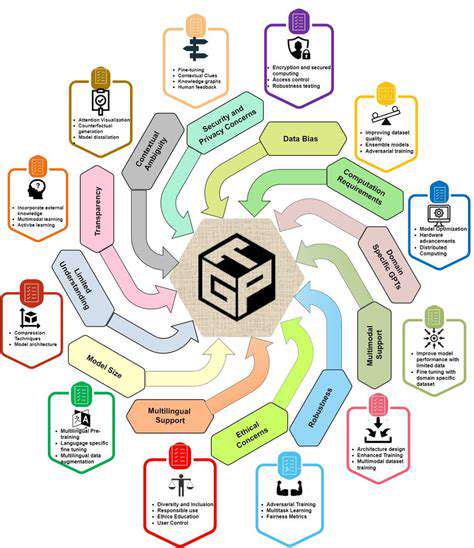

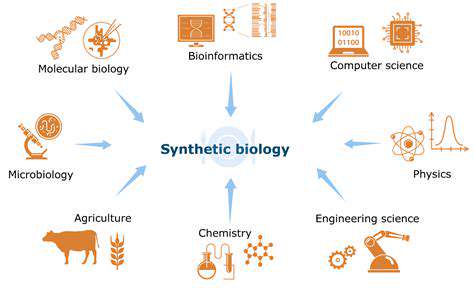

The true power of biological factories lies in their ability to utilize nature's own biochemical tools. Rather than relying on harsh chemical processes, this approach taps into the sophisticated metabolic pathways that have evolved over millennia. Cells naturally perform complex chemical transformations, and by understanding these mechanisms, scientists can reprogram them to produce valuable materials with remarkable efficiency. What makes this particularly exciting is the potential for significantly reduced environmental impact compared to conventional manufacturing methods.The enzymatic machinery within cells offers an incredibly versatile platform. Through careful genetic modifications, researchers can essentially teach microorganisms to become microscopic production facilities. This precise control enables the creation of biological systems that churn out specific compounds with both high yield and purity - something that's often challenging with traditional chemical synthesis.Genetic Engineering for Enhanced Functionality

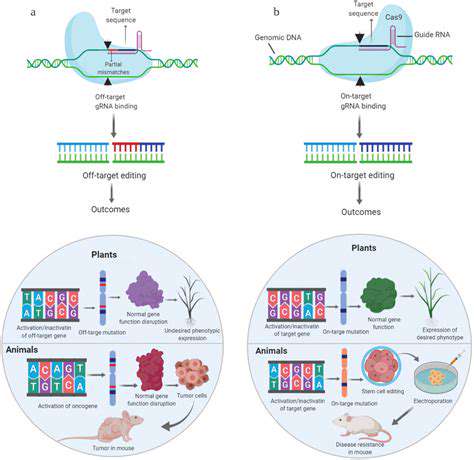

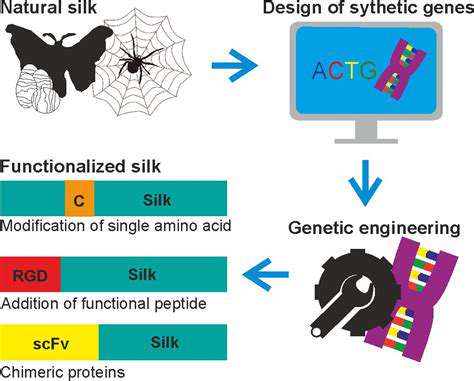

At the heart of these biological factories is the ability to modify genetic blueprints. Scientists can insert new genetic instructions or tweak existing ones, effectively upgrading the cell's production capabilities. This might involve introducing genes from completely different organisms or making subtle adjustments to enhance natural pathways. The results can be dramatic - turning ordinary microbes into specialized material-producing powerhouses.One particularly clever approach involves overcoming natural limitations in metabolic pathways. By adding entirely new biochemical routes or optimizing existing ones, researchers can dramatically boost production levels. This genetic fine-tuning allows for the creation of custom cellular factories capable of manufacturing materials that might be difficult or impossible to produce through other means.Optimizing Cellular Growth and Productivity

Even the most genetically advanced biological factory won't perform well if its living conditions aren't right. Optimizing growth conditions is like creating the perfect work environment for microscopic employees. Everything from nutrient balance to temperature and oxygen levels needs careful adjustment to ensure peak productivity. Get these factors right, and the cells will happily churn out materials at impressive rates.Beyond basic living conditions, scientists employ sophisticated techniques to boost productivity. Metabolic engineering allows for fine-tuning of the cell's internal chemical pathways, while improved cultivation methods ensure optimal growth conditions are maintained. These strategies can lead to faster production times, higher yields, and ultimately more cost-effective manufacturing processes.Metabolic Engineering Strategies for Enhanced Yield

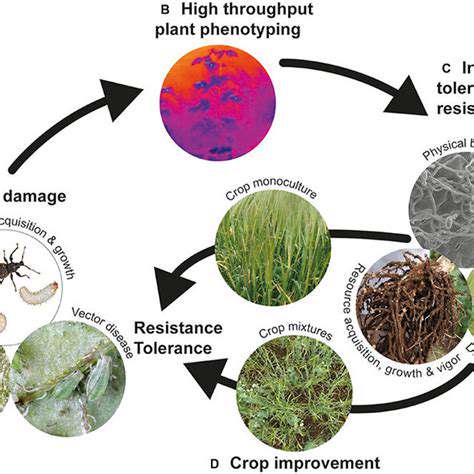

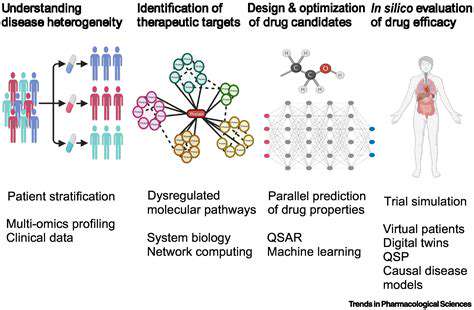

Metabolic engineering represents the next level of control over biological factories. Imagine being able to adjust the flow of biochemical reactions like valves in a complex plumbing system. That's essentially what metabolic engineers do - they redirect the cell's natural processes to favor the production of specific materials. This might involve boosting certain enzyme activities or even creating entirely new metabolic shortcuts to improve efficiency.Choosing Appropriate Host Organisms

Not all microorganisms are created equal when it comes to material production. Selecting the right host is a bit like choosing the perfect employee for a specialized job. Some organisms grow faster, others are easier to genetically modify, and certain species naturally excel at producing specific compounds. The ideal choice balances these factors while also considering practical concerns like scalability and cost-effectiveness. Researchers must carefully evaluate candidates to find the perfect match for each material production goal.Scaling Up Biomanufacturing Processes

Taking biological factories from lab benches to industrial scales presents unique challenges. It's one thing to produce materials in small flasks, quite another to manufacture them in giant industrial bioreactors. The key lies in developing processes that maintain consistent quality and yield at massive scales. This requires innovations in both equipment design and process control, ensuring that what works in the laboratory can be successfully translated to commercial production.

Applications in Diverse Material Domains

Bio-inspired Materials for Enhanced Durability

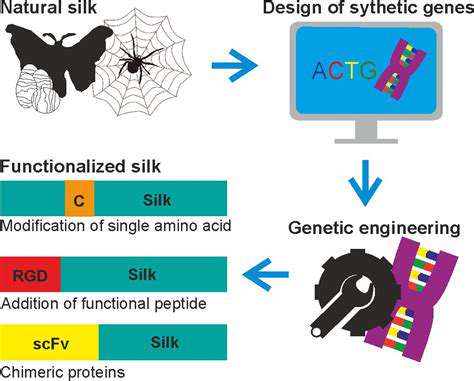

Nature has spent millions of years perfecting its material designs, and synthetic biology allows us to borrow these brilliant solutions. Spider silk stands as a prime example - stronger than steel yet incredibly flexible. By reverse-engineering these natural wonders, scientists are creating new composite materials with extraordinary properties. These bio-inspired materials could revolutionize industries from aerospace to construction, offering unprecedented combinations of strength and lightness.Perhaps even more remarkable is the potential for self-healing materials. Inspired by living tissues that can repair themselves, researchers are developing materials that automatically fix damage. Imagine infrastructure that can seal its own cracks or medical implants that maintain their integrity over time. These innovations could dramatically extend product lifespans while reducing maintenance needs and costs.Bio-Based Composites for Sustainability

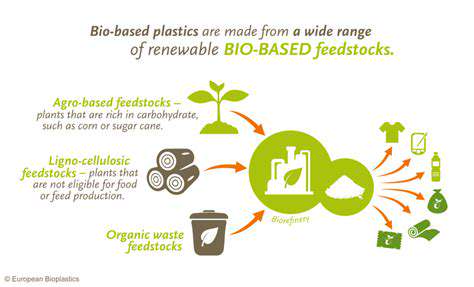

As environmental concerns grow, bio-based materials offer a promising alternative to traditional plastics. Microorganisms can be engineered to produce biopolymers that rival petroleum-based plastics in performance while being far more sustainable. These materials not only reduce reliance on fossil fuels but can also be designed to biodegrade safely at the end of their lifecycle. What's particularly exciting is how they can be customized - whether for extra strength, flexibility, or even unique properties like self-cleaning surfaces.The applications for these materials are virtually limitless. From packaging that keeps food fresh longer to medical implants that integrate seamlessly with the body, bio-based composites represent a new era of material science. They promise not just environmental benefits but also enhanced performance and entirely new functionalities that traditional materials can't match. As production methods improve, we're moving toward a future where sustainable materials become the norm rather than the exception.The development of these materials represents more than just technical progress - it's part of a broader shift toward more responsible manufacturing. By combining biological processes with engineering principles, we're creating materials that serve our needs without compromising the planet's health. This fusion of biology and technology may well hold the key to solving some of our most pressing material challenges while building a more sustainable future.